Overcoming Instrumental Limitations in Forensic Science: Advanced Methodologies and Collaborative Validation Models

This article addresses the critical challenge of instrumental and methodological limitations in forensic science settings, which often hinder the adoption of advanced technologies and evidence-based practices.

Overcoming Instrumental Limitations in Forensic Science: Advanced Methodologies and Collaborative Validation Models

Abstract

This article addresses the critical challenge of instrumental and methodological limitations in forensic science settings, which often hinder the adoption of advanced technologies and evidence-based practices. Targeting researchers, scientists, and drug development professionals, we explore the unique constraints of forensic environments, including stringent legal standards, resource limitations, and implementation barriers. Drawing from current implementation science research and analytical chemistry advancements, we present collaborative validation models, advanced techniques like comprehensive two-dimensional gas chromatography (GC×GC), and systematic implementation strategies. The article provides a comprehensive framework for troubleshooting optimization challenges and navigating legal admissibility requirements, ultimately proposing future directions for enhancing methodological rigor and technological integration in forensic research and practice.

Navigating the Unique Constraints of Forensic Research Environments

Technical Support Center

Troubleshooting Guides

Guide 1: Addressing Weak Instrumental Variables in Epidemiological Studies

Problem: Confounding bias in observational studies due to weak instrumental variables (IVs), leading to imprecise and biased effect estimates. Solution:

- Step 1: Instrument Selection: Prioritize instruments that are strongly correlated with the exposure variable. A weak correlation exacerbates bias, especially when sample sizes are small or underlying assumptions are slightly violated [1].

- Step 2: Assumption Validation: Verify that the instrumental variable meets critical assumptions: it must be associated with the exposure, not associated with confounders, and only affect the outcome through the exposure [1].

- Step 3: Sensitivity Analysis: Conduct analyses to quantify how robust your findings are to potential violations of the key assumptions. Be cautious when strong confounding is expected, as finding a valid, strong instrument becomes difficult [1].

Guide 2: Overcoming Sensitivity Limits in Fire Debris Analysis

Problem: Inability to correctly identify ignitable liquids in fire debris due to low analyte concentration or high levels of interfering pyrolysate [2]. Solution:

- Step 1: Technique Selection: Migrate from traditional Gas Chromatography-Mass Selective Detector (GC-MSD) to more sensitive techniques like Comprehensive Two-Dimensional Gas Chromatography-Time-of-Flight Mass Spectrometry (GC×GC-TOF). GC×GC-TOF has demonstrated a 10x improvement in sensitivity over GC-MSD, even in the presence of complex interfering substances [2].

- Step 2: Protocol Adherence: Follow standardized protocols for chromatographic interpretation, such as ASTM E1618-14, to ensure correct identification [2].

- Step 3: LOI Determination: Benchmark laboratory performance by determining the Limit of Identification (LOI)—the minimum on-column volume of an ignitable liquid required for correct identification. The table below summarizes typical LOIs [2]:

| Ignitable Liquid | Sample Condition | GC-MSD LOI (pL) | GC-TOF LOI (pL) | GC×GC-TOF LOI (pL) |

|---|---|---|---|---|

| Gasoline | Neat | ~0.6 | ~0.3 | ~0.06 |

| Gasoline | With Pyrolysate | ~6.2 | ~6.2 | ~0.6 |

| Diesel | Neat | ~12.5 | ~6.2 | ~1.2 |

| Diesel | With Pyrolysate | Not Identified | Not Identified | Data Provided |

Experimental Protocol for LOI Determination (Summarized from [2]):

- Sample Preparation: Prepare serial dilutions of target ignitable liquids (e.g., 75% evaporated gasoline, 25% evaporated diesel) both as neat samples and in the presence of a standardized pyrolysate.

- Instrumental Analysis: Analyze the dilutions using GC-MSD, GC-TOF, and GC×GC-TOF under matched, optimized conditions.

- Blinded Interpretation: Three experienced forensic examiners independently interpret the resulting chromatograms in accordance with ASTM E1618-14.

- LOI Calculation: The LOI is determined as the lowest on-column volume of ignitable liquid for which all three examiners make a correct identification.

Frequently Asked Questions (FAQs)

FAQ 1: What are the primary ethical considerations during a forensic assessment? Ethical forensic assessments must uphold several key principles [3]:

- Informed Consent: Ensure the individual understands the purpose, risks, benefits, and limits of confidentiality, especially when referred by a court.

- Confidentiality: Protect the individual's privacy by limiting disclosure of sensitive information and using secure data handling methods.

- Cultural Competence: Use culturally sensitive assessment tools and consider the individual's cultural background when interpreting results.

- Fairness and Avoidance of Bias: Use standardized tools, consider multiple sources of information, and seek consultation to minimize personal bias.

FAQ 2: How can I ensure my expert testimony is both ethical and effective? Effective expert testimony is built on a foundation of ethics [3]:

- Honesty and Transparency: Be clear about the limitations of your expertise and findings. Avoid overstating conclusions and disclose any potential conflicts of interest.

- Objectivity: Be aware of your own biases and use objective criteria and methods. Consider multiple perspectives.

- Preparation for Cross-Examination: Remain calm and composed, avoid defensiveness, and provide clear, concise responses to challenging questions.

FAQ 3: When using instrumental variables, why is a strong instrument so important? A strong instrument (one that is highly correlated with the exposure variable) is crucial because [1]:

- It improves the precision of the effect estimate (smaller standard error).

- It reduces bias, which is particularly pronounced with weak instruments in small samples.

- It increases the robustness of the estimate against minor violations of the IV assumptions.

FAQ 4: What is the minimum color contrast required for text in forensic reporting software to meet enhanced accessibility standards? For web-based or software interfaces, the WCAG 2.0 Enhanced Contrast (Level AAA) requirements are [4]:

- Normal Text: A contrast ratio of at least 7:1.

- Large-Scale Text: (Approximately 18pt or 14pt bold) A contrast ratio of at least 4.5:1.

The Scientist's Toolkit: Key Research Reagent Solutions

The following table details essential materials and their functions in forensic fire debris analysis, as discussed in [2].

| Item Name | Function / Explanation |

|---|---|

| Gas Chromatograph-Mass Spectrometer (GC-MS) | The standard workhorse for separating and identifying chemical components in complex mixtures like fire debris. |

| Comprehensive Two-Dimensional GC (GC×GC) | Advanced system that provides superior separation power for complex samples, reducing co-elution and improving identification. |

| Time-of-Flight Mass Spectrometer (TOF-MS) | A mass detector that offers fast acquisition rates and high sensitivity, ideal for deconvoluting complex signals. |

| ASTM E1618-14 Standard Guide | The standardized protocol for classifying ignitable liquid residues in fire debris samples, ensuring consistent analysis. |

| Petroleum-Based Ignitable Liquids | Reference standards (e.g., gasoline, diesel) used for method validation and comparison with evidence samples. |

| Pyrolysate Matrix | A simulated interfering background created by burning common materials (e.g., wood, carpet), used to test method robustness. |

Experimental Workflow and Ethical Decision-Making

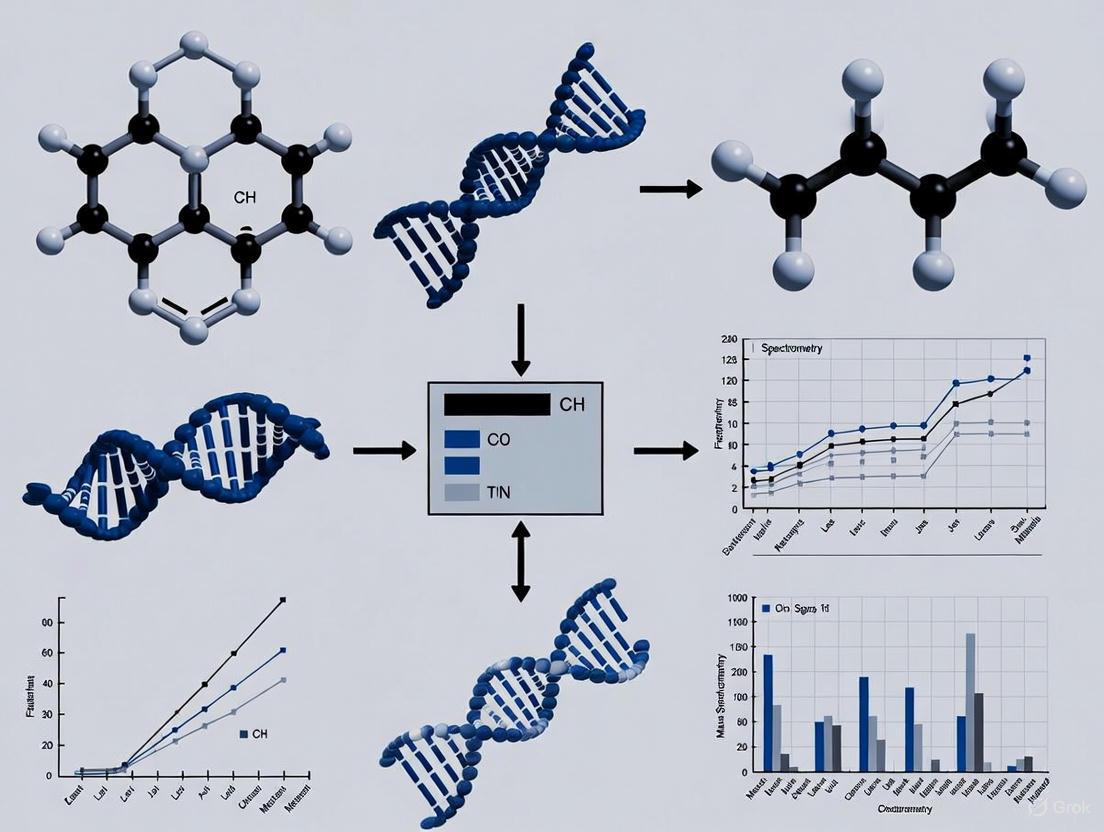

The following diagrams illustrate key instrumental and ethical workflows in forensic research.

Diagram: Fire Debris Analysis Workflow

Diagram: Ethical Forensic Assessment Flowchart

Troubleshooting Guides and FAQs

This section addresses common challenges researchers face when conducting studies in secure forensic settings and provides evidence-based strategies to overcome them.

FAQ 1: What are the most significant barriers to implementing new clinical guidelines in a forensic mental health setting?

Research identifies multilevel barriers spanning individual, organizational, and patient domains. Key challenges include:

- Individual/Provider Level: Clinician knowledge gaps, insufficient training, and perceived limited ability to adopt new guidelines [5].

- Organizational/Context Level: Lack of institutional support, resources, and implementation infrastructure [5].

- Patient Level: Difficulties adapting guidelines to specific patient needs and characteristics [5].

- Sociopolitical Level: Restrictive, security-focused environments that can hinder therapeutic relationships and implementation efforts [6] [7].

FAQ 2: How can we effectively engage forensic patients as partners in research?

Forensic Patient-Oriented Research (fPOR) faces unique challenges but can be achieved through:

- Building Trust: Actively work to navigate climates of distrust, discrimination, and restricted autonomy [6].

- Valuing Patient Voices: Address epistemic injustice by authentically incorporating patient perspectives and experiential knowledge [6].

- Trauma-Informed Approaches: Implement principles that recognize patient trauma histories [6].

- Power Redistribution: Create meaningful partnerships where patients are equal partners in research priority-setting, conduct, and knowledge translation [6].

FAQ 3: What barriers prevent research utilization among forensic mental health nursing staff?

Studies show the greatest barriers relate to organizational setting and personal characteristics [8]:

- Setting Characteristics: Lack of authority, time, and organizational support to implement changes [8].

- Personal Characteristics: Difficulty trusting research applicability to specific forensic environments [8].

- Research Accessibility: Limited availability of research reports and time to read them [8].

FAQ 4: What facilitates effective de-escalation in high-secure forensic settings?

Key facilitators include [7]:

- Therapeutic Relationships: Built on trust, fairness, consistency, and awareness of trauma-aggression links.

- Staff Skills: Empathy, respect, reassurance, sincerity, and genuine concern for patient perspectives.

- Organizational Support: Adequate resources, training, and systems that prioritize safety for all.

- Environmental Considerations: Physical spaces conducive to de-escalation.

Quantitative Data on Implementation Barriers

Table 1: BFAI Scale Scores for Guideline Implementation Barriers in Mental Health Services (n=440 clinicians) [5]

| Domain | Key Findings | Notable Barriers |

|---|---|---|

| Innovation | Most favorable perceptions; optimistic about guideline characteristics | Minimal significant barriers reported |

| Provider | Generally positive about adoption ability | Individual clinician knowledge and training |

| Context | Significant barriers identified | Organizational support and resources |

| Patient | Significant barriers identified | Adapting guidelines to specific patient needs |

Table 2: Professional Differences in Guideline Implementation Perceptions [5]

| Professional Group | Attitude Toward Guideline Embeddedness | Key Characteristics |

|---|---|---|

| Psychiatrists | Most positive | Often more familiar with guideline use |

| Psychologists | Moderately positive | -- |

| Nurses | Moderately positive | -- |

| Counsellors | Least positive | -- |

Experimental Protocols for Barrier Assessment

Protocol 1: Assessing Multilevel Barriers Using the Barriers and Facilitators Assessment Instrument (BFAI)

Application: Quantitative assessment of guideline implementation barriers in clinical settings [5].

Methodology:

- Instrument: Administer the BFAI, a validated 27-item measure rated on a 5-point Likert scale (1=fully disagree to 5=fully agree) [5].

- Domains Assessed:

- Innovation characteristics

- Provider capabilities and attitudes

- Contextual/organizational factors

- Patient-related factors

- Data Analysis: Calculate composite scores at both scale and item levels. Use ANOVA and chi-square tests to analyze professional differences.

Implementation Context: Originally used with 440 CAMHS clinicians across Sweden (52% response rate) ahead of nationwide implementation program [5].

Protocol 2: Qualitative Assessment of De-escalation Barriers in High-Secure Settings

Application: Identify barriers and facilitators to effective conflict management in forensic hospitals [7].

Methodology:

- Design: Qualitative study using semi-structured individual interviews and focus groups.

- Participants: Multiple stakeholders - patients, carers, and staff (clinical, security, administrative).

- Framework: Data collection and analysis informed by the Theoretical Domains Framework and COM-B behaviour change model.

- Analysis: Framework analysis to identify themes related to capabilities, opportunities, and motivations.

Sample Characteristics: 8 patients, 4 carers, and 25 staff members in a high-secure hospital in England [7].

Protocol 3: Assessing Readiness for Forensic Patient-Oriented Research (fPOR)

Application: Identify determinants of readiness to implement patient-oriented research in secure forensic settings [6].

Methodology:

- Design: Qualitative interview study guided by the Consolidated Framework for Implementation Research (CFIR).

- Participants: 30 staff members and 5 patients in a high-secure forensic program.

- Analysis: Thematic analysis approach, with coding initially informed by CFIR domains.

- Output: Identification of implementation determinants across five CFIR domains: intervention characteristics, inner and outer settings, individuals involved, and implementation process.

Barrier Classification Diagram

This diagram illustrates the hierarchical relationship between multilevel barriers in forensic research settings, showing how primary barrier categories branch into specific challenge areas.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Methodological Tools for Forensic Implementation Research

| Research Tool | Function | Application Context |

|---|---|---|

| Barriers and Facilitators\nAssessment Instrument (BFAI) | Quantitatively measures modifiable implementation barriers across four domains: Innovation, Provider, Patient, and Context [5]. | Guideline implementation studies in mental health settings [5]. |

| Consolidated Framework for\nImplementation Research (CFIR) | Provides taxonomy of implementation determinants; guides data collection and analysis across five major domains [6]. | Assessing readiness for patient-oriented research in complex healthcare settings [6]. |

| COM-B Behaviour Change Model | Identifies factors needed for behaviour change: Capability, Opportunity, Motivation leading to Behaviour [7]. | Understanding barriers to effective de-escalation techniques in secure settings [7]. |

| Theoretical Domains Framework (TDF) | Comprehensive framework covering evidence-based factors influencing behaviour change [7]. | Informing interview guides and analysis of clinical practice behaviours [7]. |

| Qualitative Interview Guides | Semi-structured protocols for exploring stakeholder experiences and perceptions [6] [7]. | Gathering rich data from patients, carers, and staff in forensic settings [6] [7]. |

| Framework Analysis | Systematic approach to qualitative data analysis using predefined categories [7]. | Analyzing focus group and interview data within theoretical frameworks [7]. |

For researchers and scientists developing novel forensic methods, navigating the legal standards for the admissibility of expert testimony is crucial. The judicial system acts as the ultimate gatekeeper for the implementation of new scientific techniques. Your work must ultimately satisfy the requirements of the legal framework—Frye, Daubert, or Mohan—to be deemed reliable and admissible in court. Understanding these standards is essential for overcoming instrumental limitations and ensuring that your research has a meaningful impact on the justice system.

FAQ: Understanding the Legal Frameworks

What is the Frye Standard?

The Frye Standard, or the "general acceptance test," originates from the 1923 case Frye v. United States [9]. It stipulates that expert opinion based on a scientific technique is admissible only if the technique is "sufficiently established to have gained general acceptance in the particular field in which it belongs" [10]. The court's ruling focused on the admissibility of a systolic blood pressure deception test, a precursor to the polygraph [9].

- Core Principle: The scientific principle or discovery must be past the experimental stage and have gained general acceptance in its relevant scientific community [9] [10].

- Practical Application: Proponents of a novel scientific technique may need to provide multiple experts to demonstrate its validity and general acceptance. Courts may examine scholarly papers, books, and judicial precedents to make this determination [11].

- Current Status: While superseded by Daubert in federal courts, Frye remains the standard in several state courts, including California, Illinois, New York, and Pennsylvania [12] [10].

What is the Daubert Standard?

The Daubert Standard was established in the 1993 U.S. Supreme Court case Daubert v. Merrell Dow Pharmaceuticals, Inc. [13]. It superseded the Frye standard in federal courts, ruling that the Federal Rules of Evidence, particularly Rule 702, provided a more flexible framework for admissibility [13] [14]. Under Daubert, the trial judge acts as a "gatekeeper" to ensure that any expert testimony is not only relevant but also reliable [13].

The standard was clarified in two subsequent Supreme Court cases, known collectively with Daubert as the "Daubert Trilogy" [14]:

- General Electric Co. v. Joiner (1997): Held that an appellate court should review a trial court's decision to admit or exclude expert testimony under an "abuse of discretion" standard. It also emphasized that an expert's conclusions must be connected to their underlying data [13] [15].

- Kumho Tire Co. v. Carmichael (1999): Extended the judge's gatekeeping function described in Daubert to all expert testimony, including non-scientific technical or other specialized knowledge [13] [14].

What are the Five Daubert Factors?

To assess reliability, judges consider several flexible factors [13] [14] [15]:

- Testing and Falsifiability: Whether the expert’s theory or technique can be (and has been) tested.

- Peer Review: Whether the method has been subjected to peer review and publication.

- Error Rate: The known or potential error rate of the technique.

- Standards and Controls: The existence and maintenance of standards controlling the technique's operation.

- General Acceptance: The degree to which the theory or technique is generally accepted within the relevant scientific community.

What is the Mohan Standard?

The Mohan Standard originates from the 1994 Canadian Supreme Court case R. v. Mohan [16]. It establishes a four-factor test for the admissibility of expert evidence, with a strong emphasis on preventing the fact-finding process from being distorted by unreliable science [16] [17].

The standard involves a two-stage analysis [17]:

- Threshold Requirements: The evidence must be:

- Relevant to the case.

- Necessary to assist the judge or jury (the trier of fact) in understanding a matter outside their knowledge and experience.

- Absent of any exclusionary rule.

- Provided by a properly qualified expert.

- For novel science, the underlying science must be shown to be reliable for its intended purpose.

- Cost-Benefit Analysis (Gatekeeper Role): The judge must weigh the probative value of the evidence against its potential prejudicial effect, ensuring its admission does not undermine the trial process [16] [17].

Troubleshooting Guide: Common Experimental Hurdles and Legal Admissibility

When developing a novel forensic method, researchers often face specific technical challenges that can later become legal obstacles. The following guide outlines common issues and the steps to address them within the relevant legal framework.

| Experimental Challenge | Impact on Admissibility | Corrective Protocol & Legal Strategy |

|---|---|---|

| Untested Novel Methodology | Fails the Daubert "testing" factor and Frye/Mohan "general acceptance" requirements [13] [9] [16]. | 1. Hypothesis-Driven Validation: Design a series of experiments to test the method's underlying principles under controlled conditions.2. Document Everything: Meticulously record all protocols, raw data, and analytical procedures to establish a verifiable foundation. |

| Unknown or High Error Rate | A high or unquantified error rate is a major weakness under Daubert [14] [15] and can prevent general acceptance under Frye and Mohan. | 1. Error Rate Study: Conduct specific studies to determine the method's false positive and false negative rates using known samples.2. Statistical Analysis: Employ robust statistical models to calculate confidence intervals for your results. Report these rates transparently. |

| Lack of Standardized Protocols | Raises doubts about reliability for Daubert ("standards and controls") and makes general acceptance (Frye/Mohan) unlikely [11] [15]. | 1. Develop SOPs: Create detailed, step-by-step Standard Operating Procedures (SOPs) for the entire analytical process.2. Inter-laboratory Validation: If possible, organize a round-robin trial where multiple independent labs test your SOPs to demonstrate reproducibility. |

| Limited Peer-Reviewed Publication | Weakens the method's standing under Daubert's "peer review" factor and is a significant barrier to general acceptance (Frye) [13] [9]. | 1. Target Reputable Journals: Submit your validated methods and findings to peer-reviewed scientific journals in your field.2. Present at Conferences: Present your work at scientific conferences to solicit feedback and build recognition within the scientific community. |

Workflow Visualization: Navigating the Legal Standards

The following diagrams illustrate the logical decision processes a court follows when applying the Daubert, Frye, and Mohan standards.

Daubert Standard Admissibility Workflow

Frye & Mohan Standards Admissibility Workflow

The Scientist's Toolkit: Research Reagent Solutions

For forensic scientists developing methods intended for legal admissibility, the "reagents" extend beyond chemicals to include the foundational elements of scientific and legal validity.

| Tool / Solution | Function in Experimental Design | Role in Legal Admissibility |

|---|---|---|

| Blinded Validation Studies | Tests the method's accuracy and potential for analyst bias by using samples with known identities that are unknown to the analyst during testing. | Directly addresses Daubert factors of testing and error rate, and builds a record of reliability for Frye and Mohan [15]. |

| Standard Reference Materials (SRMs) | Provides a certified, uniform material with known properties to calibrate equipment and validate experimental procedures across different labs and over time. | Establishes the "existence and maintenance of standards and controls," a key Daubert factor, and supports the reproducibility required for general acceptance [11]. |

| Proficiency Testing Programs | Allows a laboratory or researcher to assess their analytical performance by testing their method against external, challenging samples. | Generates empirical data on the method's (and the analyst's) real-world performance and error rate, crucial for all legal standards [14]. |

| Statistical Analysis Software & Expertise | Enables the rigorous quantification of results, calculation of error rates, confidence intervals, and the probabilistic interpretation of data. | Essential for establishing a known error rate for Daubert and providing a transparent, quantitative basis for the expert's opinion under Mohan [16] [15]. |

| Legal Databases (e.g., Westlaw, LexisNexis) | Allows researchers to study case law, prior judicial rulings on similar scientific evidence, and the evolving application of Daubert/Frye in their jurisdiction. | Informs the experimental design to preemptively address common legal challenges and understand the threshold for "general acceptance" [9] [12]. |

Current State of Implementation Research in Forensic Contexts

Technical Support Center: FAQs & Troubleshooting Guides

This technical support center provides targeted guidance for researchers and scientists overcoming instrumental limitations in forensic settings.

Frequently Asked Questions (FAQs)

Q: Our GC-QMS analysis is yielding high limits of detection (LOD), hindering the identification of trace analytes in alternative matrices like hair or oral fluid. What solutions can improve sensitivity?

A: High LODs can be addressed with instrumental configurations that enhance the signal-to-noise ratio (S/N). Two effective approaches are:

- Two-Dimensional Chromatography: Technologies like a Deans Switch can be implemented. This setup uses a switching valve to transfer only a specific segment of the gas chromatograph's eluent, containing your analytes of interest, to a second analytical column. This process eliminates many co-eluting interferents, significantly increasing the S/N and achieving LODs as low as 50 ppt (1 pg on column) [18].

- Tandem Mass Spectrometry (MS-MS): Modern GC-MS-MS instruments fragment ions in a collision cell, and the resulting product ions are analyzed by a second mass spectrometer. This reduces chemical noise substantially, offering LODs of less than 1 ppt and is ideal for analyzing low-concentration substances like LSD in blood or nerve agent metabolites [18].

Q: How can we validate the findings from AI-driven digital evidence analysis tools for admissibility in court?

A: The reliability of AI tools is a critical challenge. Key steps for validation include:

- Algorithmic Transparency: Scrutinize the "black box" problem. Work with vendors to understand the model's decision-making process to the greatest extent possible [19].

- Reference Standards: Utilize physical reference standards and data from authoritative bodies like the National Institute of Standards and Technology (NIST) to validate your laboratory's analytical methods and ensure accurate results [20].

- Standardized Protocols: Adhere to standards and guidelines developed by organizations such as NIST's Organization of Scientific Area Committees (OSAC) for Forensic Science. These define minimum requirements and best practices to ensure forensic analysis is reliable and reproducible [20].

Q: Our forensic investigations now include IoT devices, which use diverse operating systems and store volatile data. What is the standard approach for data acquisition?

A: A standardized approach for IoT data acquisition is still evolving due to the heterogeneity of devices. However, core principles include:

- Rapid Evidence Preservation: Prioritize the capture of volatile data, as it can be lost upon device power loss. Develop specialized techniques for immediate data preservation [21].

- Tool Diversification: Employ a suite of advanced forensic tools capable of handling a wide range of operating systems and proprietary data storage methods [19] [21].

- Holistic Analysis: Integrate data from multiple IoT devices (e.g., wearables, smart home appliances) to construct a comprehensive timeline and view of digital evidence [21].

Q: What are the primary challenges when attempting to collect digital evidence from cloud environments?

A: Cloud forensics presents several distinct hurdles:

- Data Fragmentation: Evidence can be distributed across geographically dispersed servers, requiring coordination with multiple cloud service providers and potentially extending evidence collection to weeks or months [19].

- Tool Limitations: Traditional forensic tools designed for localized data often struggle with the petabyte-scale, unstructured nature of cloud data (e.g., log streams, time-series metadata) [19].

- Legal Inconsistencies: Cross-border evidence retrieval is complicated by conflicts in data sovereignty laws (e.g., EU GDPR vs. U.S. CLOUD Act), often necessitating case-by-case legal negotiations [19].

Troubleshooting Common Experimental Workflows

Table 1: Troubleshooting Instrumental Analysis in Forensic Toxicology

| Symptom | Potential Cause | Solution | Underlying Principle |

|---|---|---|---|

| High signal noise and poor LOD | Chemical interference from the sample matrix; low analyte signal. | Implement GC with two-dimensional chromatography (e.g., Deans Switch) or upgrade to a GC-MS-MS system [18]. | Increases the signal-to-noise ratio (S/N) by physically separating analytes from interferents or reducing noise via selective fragmentation [18]. |

| Non-linear calibration curves at high concentrations | Contribution of analyte isotope ions to the abundance of the monitored deuterated internal standard ions [18]. | Increase the concentration of the internal standard or re-evaluate the selected ions for the internal standard to minimize interference [18]. | Using a deuterated internal standard corrects for preparation losses, but its natural isotopes can cause artificial depression of calculated analyte concentration at high levels [18]. |

| Inaccurate quantification | Loss of analyte during extraction or inconsistent instrument performance. | Use a deuterated internal standard, which is chemically identical but distinguishable by MS, and add it to all specimens, controls, and calibrators before extraction [18]. | The internal standard corrects for variability in extraction efficiency and instrument response, improving accuracy and precision [18]. |

Table 2: Troubleshooting Digital Forensics Investigations

| Symptom | Potential Cause | Solution | Application Context |

|---|---|---|---|

| Inability to extract data from a mobile device | Advanced device encryption or a sophisticated operating system. | Use advanced mobile forensics software with capabilities for automated decryption and data recovery. Leverage AI-driven tools to analyze extracted data [21]. | Mobile device forensics involving modern smartphones. |

| Data volatility in IoT devices | IoT device data is stored temporarily in memory and lost upon power cycling. | Refine data capture methods to prioritize volatile memory acquisition using specialized hardware and software tools [21]. | Investigations involving smart home devices, wearables, or vehicle infotainment systems. |

| Difficulty correlating user activity on a Windows system | Isolated artifacts do not provide a complete picture of the event timeline. | Correlate multiple artifacts using a shared Logon ID. Create a "super timeline" with forensic software like log2timeline to reconstruct events [22]. |

Windows endpoint forensics, particularly for tracking user actions post-authentication. |

Detailed Experimental Protocols

Protocol 1: Analysis of Drugs in Biological Matrices using GC-QMS

1. Sample Preparation:

- Extraction: Chemically extract analytes from the biological matrix (e.g., blood, urine) using a validated liquid-liquid or solid-phase extraction protocol [18].

- Derivatization: In most cases, derivatize the extracted analytes to increase their volatility and thermal stability for GC analysis [18].

2. Instrumental Analysis:

- Gas Chromatograph (GC) Setup:

- Column: Use a fused-silica capillary column.

- Carrier Gas: Helium or Hydrogen.

- Oven Program: Implement a temperature ramp optimized for the compounds of interest. "Fast GC" techniques with rapid heating rates can be applied to reduce analysis time [18].

- Mass Spectrometer (QMS) Setup:

- Ionization Mode: Typically use Electron Ionization (EI) at 70 eV, which produces reproducible fragment ion spectra [18].

- Scan Mode: For confirmatory analysis, operate in Selected Ion Monitoring (SIM) mode. Monitor a minimum of three characteristic ions for the target analyte and two for the internal standard to confirm identification via ion abundance ratios [18].

3. Quantification:

- Prepare a calibration curve by analyzing calibrators containing known concentrations of the analyte.

- Add a constant amount of a deuterated internal standard to all samples and calibrators before extraction.

- The analyte concentration in an unknown is calculated based on the ratio of the analyte's signal to the internal standard's signal against the calibration curve [18].

Protocol 2: Forensic Timeline Creation from Windows Endpoints

1. Evidence Collection:

- Registry: Acquire registry hives (e.g.,

SYSTEM,SOFTWARE,SAM,SECURITY,NTUSER.DAT) from the system root and user profiles [22]. - Filesystem: Capture

$MFT(Master File Table), Prefetch files (C:\Windows\Prefetch), and Jumplist files (C:\Users\[user]\AppData\Roaming\Microsoft\Windows\Recent\AutomaticDestinations) [22]. - Event Logs: Export relevant event logs (e.g.,

Security.evtx,System.evtx,Microsoft-Windows-Shell-Core/Operational.evtx) [22]. - Memory (Optional): For a live system, acquire a physical memory dump to capture volatile artifacts [22].

2. Artifact Processing & Correlation:

- Parsing: Use forensic tools to parse the collected artifacts. For example, extract

Logon ID(e.g.,0x123456) from a4624 Loginevent in the Security log [22]. - Correlation: Use the

Logon IDas a pivot to find related activity across other artifacts. The sameLogon IDmay be found in process creation events (4688), file access records in the$MFT, and registry key accesses [22]. - Timeline Generation: Consolidate timestamps from all parsed artifacts into a unified "super timeline" using tools like log2timeline/Plaso to reconstruct the sequence of events [22].

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Forensic Research & Analysis

| Item | Function & Application |

|---|---|

| Deuterated Internal Standards | Chemically identical, isotopically labeled analogs of target analytes. Added to samples to correct for losses during extraction and matrix effects during instrumental analysis, significantly improving quantification accuracy and precision in GC-MS [18]. |

| Standard Reference Materials (SRMs) | Physical standards certified by metrology institutes like NIST. Used to validate analytical methods, calibrate instruments, and ensure the accuracy and reliability of forensic measurements across disciplines from DNA analysis to toxicology [20]. |

| Advanced Mobile Forensics Software | Software suites capable of bypassing encryption, recovering deleted files, and parsing data from complex mobile apps and IoT devices. Essential for acquiring digital evidence from the vast ecosystem of modern consumer devices [21]. |

| Forensic Artifact Databases | Comprehensive guides and databases (e.g., for Windows artifacts) that document the location, structure, and interpretive value of digital traces. Critical for understanding the meaning of evidence and correlating activities across a system [22]. |

Experimental Workflow & Logic Diagrams

Technology Readiness Levels (TRL) Assessment for Forensic Applications

This technical support center provides resources for researchers and scientists applying Technology Readiness Level (TRL) assessments to forensic methods and instruments. The TRL framework, originally developed by NASA, is a nine-level scale used to systematically assess the maturity of a technology, from basic principle observation (TRL 1) to full system proven in operational environment (TRL 9) [23]. In forensic science, this assessment is crucial for overcoming instrumental limitations and ensuring that new methods meet the rigorous legal standards required for courtroom admissibility [24]. This guide addresses frequent challenges through troubleshooting guides, FAQs, and detailed protocols to support your research and development efforts.

Troubleshooting Guides and FAQs

Frequently Asked Questions

Q1: What are the most critical factors for transitioning a forensic method from research (TRL 3-4) to validation (TRL 5-6)?

A: The transition from controlled laboratory validation to relevant environment testing is a major hurdle. Success depends on three factors:

- Inter-laboratory Validation: Initiate collaborative trials with other labs to test the robustness and reproducibility of your method [24].

- Error Rate Analysis: Begin quantifying the method's known or potential error rate. This is a critical requirement for meeting legal admissibility standards like the Daubert Standard [24].

- Standardization: Develop standard operating procedures (SOPs) that can be consistently followed in different environments, moving beyond a single lab's optimized conditions [24].

Q2: Our GC×GC-TOF method shows excellent separation in clean samples but performance drops with complex, contaminated forensic debris. How can we improve this?

A: This is a common instrumental limitation when moving to higher TRLs with real-world samples.

- Symptom: Decreased sensitivity and identification confidence in the presence of pyrolysate or other sample matrix interferences.

- Solution: The superior peak capacity of GC×GC-TOF is your primary tool. Optimize the sample preparation step to reduce matrix complexity before injection. Furthermore, leverage the 10x greater sensitivity of GC×GC-TOF over traditional GC-MS to dilute the sample, thereby reducing the concentration of interferents while maintaining a detectable signal for the target analytes [2].

Q3: What specific evidence is needed to demonstrate that a method is "generally accepted" (Frye Standard) or has a "known error rate" (Daubert Standard)?

A: The legal framework for forensic evidence requires proactive validation [24].

- For "General Acceptance": Provide a body of peer-reviewed publications citing your work and independent studies that successfully apply your method. Documentation of talks or training sessions at major forensic science conferences can also serve as evidence.

- For "Known Error Rate": You must conduct and document intra- and inter-laboratory validation studies that specifically measure the method's false positive and false negative rates under controlled conditions. This quantitative data is essential [24].

Troubleshooting Common TRL Progression Challenges

Challenge: Inconsistent Results During Inter-Laboratory Trials (TRL 4 to TRL 5)

- Potential Cause: Variances in instrument calibration, reagent suppliers, or analyst technique between laboratories.

- Solution: Create a detailed and unambiguous Experimental Protocol that includes:

- Instrument Calibration Logs: Specify acceptable tolerance limits for key performance metrics.

- Reagent Specifications: Define brand, purity, and lot-number verification requirements for all critical reagents.

- Reference Standard Data: Provide a table of expected results for a certified reference material that all labs must achieve before commencing the trial.

Challenge: Method is Too Complex or Expensive for Widespread Adoption (TRL 7 to TRL 8)

- Potential Cause: The development focused solely on technical performance without considering operational sustainability, a concept known as "frugal forensics" [25].

- Solution: Re-evaluate the method against the PAACSS attributes (Performance, Accessibility, Availability, Cost, Simplicity, Safety) [25]. Can a simpler, more readily available detector be used without compromising critical data? Can the workflow be simplified for high-throughput environments? Adapting the method to be more economical and resilient is key to sustainable implementation.

Experimental Protocols and Data

Detailed Protocol: Assessing Limits of Identification for Ignitable Liquids

This protocol is adapted from a study benchmarking modern instrumental performance and is critical for establishing a method's sensitivity during validation phases (TRL 4-5) [2].

1. Objective: To determine the Limit of Identification (LOI) for petroleum-based ignitable liquids (e.g., gasoline, diesel) using GC×GC-TOFMS in the presence of interfering pyrolysate.

2. Materials and Equipment:

- Instrumentation: Comprehensive Two-Dimensional Gas Chromatograph coupled to a Time-of-Flight Mass Spectrometer (GC×GC-TOFMS).

- Columns: Primary column (e.g., 5%-Phenyl polysilphenylene-siloxane), and a secondary column (e.g., 50%-Phenyl polysilphenylene-siloxane) connected via a thermal modulator.

- Samples: Neat 75% evaporated gasoline, neat 25% evaporated diesel, and these same liquids spiked into a matrix of fire debris pyrolysate.

- Syringes: Calibrated micro-syringes for precise, sub-microliter injections.

3. Procedure:

- Step 1 - Neat Sample Analysis:

- Prepare a serial dilution of the neat gasoline and diesel samples.

- Inject each dilution into the GC×GC-TOFMS system using a standardized method.

- Determine the smallest volume (in picoliters on-column) that three independent, experienced forensic examiners can correctly identify based on chromatographic data in accordance with ASTM E1618-14.

- Step 2 - Analysis with Interference:

- Spike the same dilution series of ignitable liquids into a standardized pyrolysate matrix.

- Repeat the injection and identification process.

- Document the lowest identifiable volume for each liquid in the interfering matrix.

- Step 3 - Data Analysis:

- The LOI is defined as the lowest on-column volume that yields a correct identification by all examiners.

- Compare the LOIs for neat versus spiked samples to quantify the impact of the matrix.

4. Expected Outcomes and Benchmarking Data: The following table summarizes typical LOI data, providing a benchmark for your own assessments.

Table 1: Limits of Identification for Ignitable Liquids [2]

| Ignitable Liquid | Sample Condition | GC-MSD LOI (pL on-column) | GC-TOFMS LOI (pL on-column) | GC×GC-TOFMS LOI (pL on-column) |

|---|---|---|---|---|

| Gasoline | Neat | ~0.6 | ~0.3 | <0.06 |

| Gasoline | With Pyrolysate | ~6.2 | ~6.2 | ~0.6 |

| Diesel | Neat | ~12.5 | ~6.3 | ~1.3 |

| Diesel | With Pyrolysate | Not Identified | Not Identified | See Note |

Note: In the cited study, diesel could not be correctly identified at the tested concentrations with pyrolysate using GC-MSD or GC-TOFMS, demonstrating the superior capability of GC×GC-TOFMS for complex samples [2].

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Forensic Method Development (TRL 3-5)

| Item | Function / Rationale |

|---|---|

| Certified Reference Materials (CRMs) | Provides a ground-truth standard for method validation and calibration. Essential for demonstrating accuracy and precision. |

| ASTM E1618-14 Standard Guide | Defines the standard classification for ignitable liquids found in fire debris. Critical for ensuring your method's output is forensically relevant and interpretable. |

| Custom-Made Pyrolysate Matrix | A standardized, characterized mixture of combustion products from common materials (e.g., wood, carpet). Used to test method robustness and LOI in realistic, complex matrices [2]. |

| Stable Isotope-Labeled Internal Standards | Used in quantitative assays to correct for sample loss during preparation and matrix effects during analysis, improving data reliability. |

| Quality Control (QC) Check Samples | A stable, well-characterized sample run with every batch to monitor instrument performance and data integrity over time. |

Visualization of Workflows and Relationships

TRL Assessment Workflow for Forensic Methods

This diagram outlines the logical progression and key decision points for advancing a forensic analytical method through Technology Readiness Levels.

GC×GC Instrumentation and Data Flow

This workflow details the key components and process flow in Comprehensive Two-Dimensional Gas Chromatography, a technology with high potential for forensic applications.

Advanced Analytical Techniques and Implementation Strategies for Forensic Settings

Forensic scientists routinely encounter highly complex analytical problems related to crime scenes, from drug identification to trace evidence analysis. Traditional gas chromatography-mass spectrometry (GC-MS) has long been the gold standard in forensic trace evidence analysis due to its ability to separate and analyze mixture components. However, its primary limitation lies in coelution of compounds in complex mixtures, which can prevent accurate identification and quantification. Fortunately, advanced separation technologies like comprehensive two-dimensional gas chromatography (GC×GC–MS) and high-resolution mass spectrometry (HRMS) are now providing forensic scientists with powerful tools to overcome these limitations, enabling more confident characterization of evidence in cases involving drugs, explosives, ignitable liquids, and other challenging samples.

Troubleshooting Guides

GC×GC-MS Troubleshooting Guide

| Symptom | Possible Cause | Solution |

|---|---|---|

| Background "shadow" or elevated baseline in specific regions of the chromatographic plane [26] | Column bleed from either the first-dimension or second-dimension column, especially at elevated oven temperatures. | - Ensure the column temperature limit is not exceeded.- Perform routine column maintenance and condition columns properly.- Use high-quality, thermally stable columns. |

| Low intensity (sensitivity) of minor components [26] | - Coelution masking minor components in 1D-GC.- Suboptimal modulation conditions. | - Optimize the modulator settings.- Verify that the GC×GC–MS method provides increased sensitivity over GC–MS for minor components. |

| Inability to differentiate between samples with similar chemical profiles (e.g., automotive paints) [26] | Insufficient chromatographic separation in the first dimension, leading to coelution. | - Utilize the second dimension to separate coeluting peaks (e.g., α-methylstyrene and n-butyl methacrylate).- Further optimize method parameters like temperature ramp and column selection. |

HRMS Troubleshooting Guide

| Symptom | Possible Cause | Solution |

|---|---|---|

| Poor reproducibility of peptide/protein quantitation [27] | - Inconsistent sample preparation.- LC-MS system performance issues. | - Use standardized sample prep kits (e.g., EasyPep MS Sample Prep Kits) for consistent protein extraction, digestion, and clean-up [27].- Quantify peptides before LC-MS analysis.- Recalibrate the system using calibration solutions. |

| Reduced instrument sensitivity over time [28] | - Contamination of the ion source or mass analyzer.- Incorrect mass calibration. | - Perform regular, scheduled cleaning and maintenance of the ion source.- Re-tune and re-calibrate the instrument according to the manufacturer's specifications. |

| Difficulty identifying unknown compounds in complex matrices (e.g., herbal medicine, drugs of abuse) [28] | - Reliance on targeted data acquisition methods.- Insufficient mass accuracy or resolution. | - Employ untargeted data acquisition techniques like data-independent acquisition (DIA) or background exclusion data-dependent analysis (DDA).- Use hybrid HRMS instruments (e.g., Q-TOF, Orbitrap) that combine accurate mass measurement with fragmentation capabilities. |

Frequently Asked Questions (FAQs)

Q: When should I consider using GC×GC–MS over standard GC–MS in my forensic analysis?

A: You should consider GC×GC–MS when analyzing highly complex mixtures where component coelution is suspected or when you need to detect minor components that are hidden by major constituents in a standard GC-MS run. This is particularly valuable for evidence such as sexual lubricants, automobile paints, tire rubber, and ignitable liquids in fire debris, where the added separation dimension provides a unique chemical "fingerprint" and significantly increased sensitivity [26] [29].

Q: What are the main advantages of High-Resolution Mass Spectrometry (HRMS) in a forensic toxicology setting?

A: HRMS provides two key advantages. First, its high mass resolving power allows it to distinguish between compounds with the same nominal mass but different exact masses, reducing false positives. Second, it is exceptionally well-suited for non-targeted screening because it can collect full-spectrum accurate mass data without prior knowledge of the compounds present. This is crucial for detecting novel drugs, metabolites, or unexpected toxins. Furthermore, modern HRMS instruments are now capable of reliable quantitative analysis, challenging the dominance of traditional tandem mass spectrometers (QqQ) in many fields [30] [28].

Q: Our lab is setting up a method for organic gunshot residue (OGSR) analysis. Should we choose GC–MS or LC–MS/MS?

A: Both techniques are recommended by standards bodies, but they have different strengths. GC–MS is excellent for characterizing the volatile and semi-volatile organic components in unburnt or partially burnt smokeless powder. LC–MS/MS, particularly with atmospheric pressure chemical ionization (APCI), is often more suitable for trace-level analysis of OGSR collected from shooters' hands, as it can detect a broader range of stabilizers and explosives at very low concentrations (parts-per-billion levels) [31]. The choice may depend on your specific target analytes and the sample collection method.

Q: What is the most common source of problems in GC and GC×GC systems, and how can it be managed?

A: The inlet is the most common source of issues. It is subjected to high temperatures and has multiple consumables (liners, septa, O-rings) that require routine maintenance. Problems like peak tailing, analyte breakdown, and poor reproducibility often originate here. To manage this:

- Regularly inspect and replace the inlet liner, especially when analyzing "dirty" samples that leave non-volatile residues [32].

- For active compounds, use a highly deactivated liner and column to prevent adsorption [32].

- Ensure proper installation to avoid dead volumes, and use liners with quartz wool to improve vaporization and trap non-volatile impurities, thereby protecting your column [32].

Experimental Protocols & Data

Protocol 1: GC×GC–MS Analysis of Forensic Lubricants

This protocol is adapted from the analysis of oil-based personal lubricants for sexual assault investigations [26].

- Sample Preparation: Perform hexane solvent extraction of the lubricant sample from relevant substrates (e.g., cloth, condom remnants).

- Instrumentation:

- GC System: 7890B Gas Chromatograph (Agilent)

- Mass Spectrometer: 5977 Quadrupole MS (Agilent)

- Columns: The specific column set used can be optimized for the application.

- GC×GC–MS Conditions:

- Injection: Split-splitless injector; 1 µL injection volume.

- Carrier Gas: Helium.

- Oven Program: Temperature ramp tailored to separate components of natural oils (e.g., cocoa butter, shea butter, vitamin E oil, almond oil).

- Modulation: Use a thermal or flow modulator suitable for the comprehensive 2D separation.

- MS Detection: Electron Impact (EI) source at 70 eV; mass range: 40-550 m/z.

- Data Interpretation: Interpret the resulting 2D chromatogram as a "fingerprint." Look for patterns of isoparaffins and aldehydes. Compare the profile to a database of known lubricants to identify the brand or type.

Protocol 2: Assessing Sensitivity of Ignitable Liquid Analysis

This protocol outlines the method for determining the Limit of Identification (LOI) for ignitable liquids like gasoline and diesel in fire debris, comparing different MS platforms [29].

- Sample Preparation:

- Obtain gasoline and diesel fuel.

- Weather the liquids by evaporating 75% of gasoline and 25% of diesel under a pure nitrogen stream.

- Create a serial dilution of the weathered ignitable liquids in dichloromethane.

- Prepare a second set of dilutions using dichloromethane doped with a mixture of pyrolysates (from spruce plywood, foam underlay, and nylon carpet) to simulate a complex fire debris matrix.

- Instrumental Analysis:

- Analyze all dilutions using three different platforms under matched conditions:

- GC-MSD: Single quadrupole mass spectrometer.

- GC-TOF: Time-of-flight mass spectrometer in 1D mode.

- GC×GC-TOF: Comprehensive two-dimensional GC with TOF detection.

- Use a matched column set (5% phenyl / wax column combination) and the same temperature program optimized for each system.

- Use a split injection (e.g., 1:80) to deliver 1 µL.

- Analyze all dilutions using three different platforms under matched conditions:

- Identification:

- Have multiple experienced forensic examiners interpret the resulting chromatograms according to the standard method (ASTM E1618-14).

- The LOI is defined as the lowest on-column volume of ignitable liquid at which correct identification is consistently achieved.

The data from this experiment clearly demonstrates the superiority of GC×GC–TOF, especially for complex samples.

Table 1: Limit of Identification (LOI) for Ignitable Liquids on Different MS Platforms [29]

| Ignitable Liquid | Matrix | GC-MSD (pL on-column) | GC-TOF (pL on-column) | GC×GC-TOF (pL on-column) |

|---|---|---|---|---|

| Gasoline (75% evaporated) | Neat | ~0.6 | ~0.3 (2x better) | ~0.06 (10x better) |

| Gasoline (75% evaporated) | With Pyrolysate | ~6.2 | ~6.2 (Equivalent) | ~0.6 (10x better) |

| Diesel (25% evaporated) | Neat | ~12.5 | Data Not Provided | ~1.3 (10x better) |

| Diesel (25% evaporated) | With Pyrolysate | Could not be identified | Could not be identified | Could not be identified at tested levels |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Sample Preparation in Complex Mixture Analysis

| Item | Function | Example |

|---|---|---|

| High-pH Reversed-Phase Peptide Fractionation Kit | Reduces sample complexity before LC-MS analysis by fractionating peptides, increasing the number of quantifiable peptides/proteins in multiplexed samples [27]. | Pierce High pH Reversed-Phase Peptide Fractionation Kit (Cat. No. 84868) [27]. |

| Tandem Mass Tag (TMT) Reagents | Allows for multiplexed quantitative proteomics, enabling the simultaneous quantification of proteins from multiple samples in a single LC-MS run. | TMT or TMTpro Reagents. The labeling efficiency should be verified [27]. |

| MS Sample Preparation Kit | Ensures highly reproducible and consistent protein extraction, reduction, alkylation, digestion, and clean-up, which is critical for reliable quantitative results [27]. | EasyPep Mini/Max MS Sample Prep Kits [27]. |

| Quantitative Peptide Assay | Accurately quantifies peptide concentration before LC-MS injection to ensure equal loading across runs, improving reproducibility [27]. | Pierce Quantitative Fluorometric or Colorimetric Peptide Assay [27]. |

| System Suitability Standard | Used to assess and validate the performance of the LC-MS/MS system before running valuable samples, ensuring data quality [27]. | Pierce LC-MS/MS System Suitability Standard or HeLa Protein Digest Standard [27]. |

Workflow Visualization

In forensic settings, particularly in drug analysis, the traditional model of independent method validation by each laboratory creates significant inefficiencies. This redundancy consumes precious resources, delays the implementation of new technologies, and ultimately hinders the pace of justice and public health protection. A collaborative method validation model presents a transformative alternative, where Forensic Science Service Providers (FSSPs) using the same technology work cooperatively to standardize methods and share validation data [33]. This technical support center is designed to help researchers, scientists, and drug development professionals overcome instrumental limitations by implementing these collaborative approaches, providing troubleshooting guides and FAQs to navigate common experimental challenges.

Implementation Workflow for Collaborative Validation

The process of establishing and benefiting from a collaborative validation framework can be broken down into a series of key phases, from initial planning to ongoing optimization. The following diagram illustrates this workflow and the interaction between the originating laboratory and subsequent adopting laboratories.

Troubleshooting Guides and FAQs

Common Instrumental Issues and Solutions

Instrumental techniques in forensic drug analysis, such as GC/MS, HPLC, and FTIR, are prone to specific issues that can compromise data integrity. The table below outlines common problems and their solutions [34] [35].

| Problem Symptom | Potential Cause | Troubleshooting Steps | Prevention Tips |

|---|---|---|---|

| Drift in instrument response, inconsistent calibration | Incorrect calibration, temperature fluctuations, component wear and tear [34] [36]. | 1. Re-calibrate using fresh reference standards.2. Check and control laboratory environment (e.g., temperature).3. Inspect and replace worn components (e.g., syringe, liner) [35]. | Follow a strict calibration schedule. Perform routine maintenance. Keep detailed instrument logs. |

| Increased noise, low signal-to-noise ratio | Contaminated ion source (GC/MS), dirty flow cell (HPLC), degraded optics (FTIR), or electrical noise [34] [36]. | 1. Clean or replace contaminated parts (e.g., GC/MS ion source, HPLC flow cell).2. Ensure proper grounding of instruments.3. Use high-purity solvents and gases [34]. | Use high-purity reagents. Implement regular cleaning protocols. |

| Poor chromatographic separation, broad peaks | Degraded chromatography column, incorrect mobile phase composition, or flow rate issues [34] [37]. | 1. Condition or replace the chromatography column.2. Prepare fresh mobile phase and verify composition.3. Check for and eliminate tubing leaks or blockages [37]. | Guard columns. Follow proper column storage protocols. Filter all samples and mobile phases. |

| Inaccurate quantification, non-linear calibration curves | Sample preparation errors, contamination, or instrument detection limits [34] [37]. | 1. Re-prepare samples using validated protocols.2. Check for source of contamination (e.g., pipettes, vials).3. Verify detector linearity and dynamic range [35]. | Use calibrated pipettes. Employ clean lab techniques. Prepare fresh standard solutions. |

Frequently Asked Questions (FAQs)

Q: What is the fundamental difference between full method validation and verification in a collaborative model? A: Full validation is the comprehensive process of providing objective evidence that a method is fit for its intended purpose, performed by the originating laboratory. This includes establishing parameters like specificity, accuracy, precision, and robustness [33]. Verification is a more abbreviated process conducted by subsequent adopting laboratories. If they adhere strictly to the published method parameters, they can verify that the method performs as expected in their laboratory, thereby accepting the original published data and eliminating redundant development work [33].

Q: Our laboratory is verifying a collaboratively published GC/MS method for fentanyl analysis. We are seeing significantly lower recoveries than reported. What should we do? A: This discrepancy suggests a potential issue with your specific implementation. Follow this troubleshooting path:

- Step 1: Check Sample Preparation: Meticulously re-check your sample preparation steps against the published protocol. Ensure solvents, derivatization agents, and extraction techniques match exactly. Small deviations can cause major recovery differences [34] [37].

- Step 2: Verify Instrument Parameters: Confirm that all instrument parameters (inlet temperature, column type and dimensions, flow rate, temperature ramp, and detector settings) are identical to those published [34].

- Step 3: Contact the Originating Lab: A core tenet of the collaborative model is shared expertise. Reach out to the corresponding author of the validation paper. They have extensive experience with the method and may provide immediate insight into common pitfalls [33].

Q: How can collaborative validation help with the analysis of emerging novel psychoactive substances (NPS)? A: The rapid emergence of NPS is a major challenge. A collaborative model is ideally suited to respond [38]. When a new drug is identified, one laboratory can rapidly develop and validate an analytical method and share it immediately via publication. This allows other laboratories to bypass the development phase and quickly implement a verified method using the same instrumentation and parameters. This shared approach drastically reduces the time between a drug's emergence and the widespread capability to detect it, directly enhancing public health and safety responses [33] [38].

Q: What are the key considerations when planning a collaborative validation study to ensure others can easily verify it? A: Planning for collaboration from the outset is critical. Key considerations include:

- Use Published Standards: Build the validation protocol using relevant standards from organizations like OSAC or SWGDAM to ensure rigor and acceptability [33].

- Document Meticulously: Record every detail of the method, including instrument make/model, column lot numbers, reagent suppliers, and catalog numbers. Ambiguity is the enemy of successful verification.

- Engage Early: Consider forming a working group with other interested laboratories before beginning. This ensures the protocol meets collective needs and fosters a ready-made network for data sharing and troubleshooting [33].

Experimental Protocols for Method Verification

This section provides a detailed methodology for a key experiment in the collaborative model: the verification of a published analytical method for a drug in a forensic laboratory.

Protocol: Verification of a Published GC/MS Method for Cocaine Metabolite

1. Principle This protocol verifies the performance of a published GC/MS method for the detection and quantification of benzoylecgonine (a cocaine metabolite) in a simulated urine matrix. The verification ensures the method meets predefined performance criteria for linearity, accuracy, and precision as described in the collaborative validation publication [37].

2. Scope Applies to laboratories adopting a previously published and validated GC/MS method for confirmatory drug testing.

3. Reagents and Materials

- Reference Standards: Certified reference material of benzoylecgonine and its deuterated internal standard (e.g., Benzoylecgonine-D3).

- Solvents: HPLC-grade methanol, ethyl acetate, and deionized water.

- Derivatization Reagent: N-Methyl-N-(trimethylsilyl)trifluoroacetamide (MSTFA).

- Supplies: GC/MS system, analytical balance, micropipettes, autosampler vials, and a chromatography column identical to that specified in the published method.

4. Equipment

- Gas Chromatograph coupled with a Mass Spectrometer (GC/MS)

- Analytical balance (capable of weighing to 0.0001 g)

- Micropipettes

5. Procedure 5.1 Sample Preparation (Extraction and Derivatization):

- Precisely pipette 1 mL of negative urine control into a disposable culture tube.

- Add 100 µL of the internal standard working solution.

- Following the exact liquid-liquid extraction procedure described in the published method (e.g., add 2 mL of pH X buffer and 3 mL of ethyl acetate, vortex, centrifuge).

- Transfer the organic layer and evaporate to dryness under a gentle stream of nitrogen.

- Derivatize the residue with 50 µL of MSTFA at the specified temperature and time (e.g., 70°C for 20 minutes).

5.2 Instrumental Analysis:

- Configure the GC/MS: Set all parameters exactly as published, including inlet temperature, oven temperature program, carrier gas flow rate, and MS source/detector temperatures.

- Create a Calibration Curve: Prepare and analyze a minimum of five calibration standards (e.g., at 0, 75, 150, 300, and 500 ng/mL) in duplicate.

- Analyze Quality Control (QC) Samples: Prepare and analyze QC samples at low, medium, and high concentrations (e.g., 50, 200, 400 ng/mL) in quintuplicate to assess precision and accuracy.

6. Data Analysis

- Linearity: The calibration curve must have a correlation coefficient (r²) of ≥ 0.99.

- Accuracy: The mean calculated concentration for each QC level must be within ±15% of the theoretical value.

- Precision: The coefficient of variation (%CV) for each QC level must be ≤15%.

The method is considered successfully verified only if all above criteria are met.

The Scientist's Toolkit: Research Reagent Solutions

The following table details key materials and reagents essential for forensic drug analysis and method validation [37].

| Item | Function & Application in Forensic Analysis |

|---|---|

| Certified Reference Standards | Pure, certified materials used to identify and quantify target drug compounds and their metabolites via retention time and mass spectrum matching. Essential for calibration [37]. |

| Deuterated Internal Standards | Isotopically-labeled analogs of target analytes (e.g., Morphine-D3). Added to samples to correct for variability in sample preparation and instrument response, improving accuracy and precision [37]. |

| Derivatization Reagents (e.g., MSTFA) | Chemicals that react with functional groups (e.g., -OH, -NH2) on drug molecules to improve their volatility, thermal stability, and chromatographic behavior for GC/MS analysis [37]. |

| SPME Fibers | Solid Phase Microextraction fibers are used for solvent-less extraction and concentration of analytes from complex liquid or headspace samples, improving sensitivity [37]. |

| Functionalized Silanes | Used to develop and test new stationary phases for GC and HPLC. By changing the terminal functional group (X in X-(CH2)n-SiCl3), the surface polarity and selectivity for different drugs can be tuned [37]. |

Quantitative Data on Collaborative Model Impact

The adoption of a collaborative validation model presents significant quantitative advantages over the traditional independent approach. The table below summarizes key performance and cost differences [33].

| Metric | Traditional Independent Validation | Collaborative Model (Verification) | Impact / Savings |

|---|---|---|---|

| Estimated Time Investment | Several weeks to months per laboratory | Several days to a few weeks per laboratory | Reduction of 60-80% in labor hours [33] |

| Primary Cost Components | High personnel hours, extensive sample consumption, opportunity cost of delayed casework [33] | Primarily personnel hours for verification; minimal new method development | Significant savings in salary, samples, and opportunity cost [33] |

| Casework Output Delay | Substantial delay for each lab performing validation | Drastically reduced; implementation can follow shortly after verification | Enables faster adoption of new technology for casework [33] |

| Data Comparability | Low; methods may have minor but significant differences | High; direct cross-comparison of data between labs using identical methods is possible [33] | Strengthens scientific validity and enables shared databases |

FAQs: Integrating CFIR and TDF in Forensic Research

Q1: What are the CFIR and TDF, and why are they used together in implementation science?

The Consolidated Framework for Implementation Research (CFIR) is a comprehensive determinant framework used to identify and explain barriers and facilitators to implementing evidence-based practices. It encompasses 39 constructs across five major domains: Intervention Characteristics, Outer Setting, Inner Setting, Characteristics of Individuals, and Implementation Process [39] [40]. The Theoretical Domains Framework (TDF) is another determinant framework, comprising 128 constructs across 12 domains, derived from 33 theories of behavior change to understand influences on individual healthcare provider behavior [41].

They are often used together because they are complementary. The CFIR provides a multi-level, macro-view of implementation, including organizational and broader societal factors, while the TDF offers a more detailed, micro-view of individual-level psychological and behavioral determinants [41] [40]. Using both frameworks together allows researchers to more fully define the multi-level nature of implementation challenges, from system-wide policies down to an individual staff member's beliefs and capabilities [41].

Q2: How can these frameworks help overcome instrumental limitations in forensic research settings?

In forensic settings, "instrumental limitations" often refer to practical and contextual barriers that hinder the effective adoption of new techniques or practices, such as advanced de-escalation techniques. The combined CFIR+TDF approach provides a systematic method to diagnose these specific barriers. For example, a study in a forensic mental health unit used the TDF to identify that staff capabilities (e.g., relationship-building skills), opportunities (e.g., restrictive ward environments), and motivations (e.g., fear of patients) were all critical barriers to effectively implementing de-escalation techniques [42]. By systematically identifying barriers across different levels, targeted strategies can be developed to overcome them.

Q3: What are the common barriers to implementing new practices in secure forensic settings identified by these frameworks?

Research using these frameworks in forensic settings has identified several recurring barriers:

- Capability Barriers: Gaps in staff knowledge and specific psychological skills (e.g., empathy, emotional regulation) needed for interventions like de-escalation [42] [43].

- Opportunity Barriers: An inner setting with a punitive culture, stigmatizing beliefs against therapeutic intimacy, limited organizational resources, and a physical environment that feels inherently deprived [42] [43].

- Motivation Barriers: High levels of fear among both staff and patients, perceptions of patient dangerousness, and insufficient belief among staff that a new intervention will be beneficial [43].

Q4: What is a key consideration when designing an implementation study using both CFIR and TDF?

A key consideration is to avoid redundancy and unnecessary complexity. Researchers should clearly state how each framework contributes uniquely to addressing their study's purposes. For instance, the CFIR might be used to guide a broad evaluation of organizational readiness, while the TDF could then be applied to conduct a deep dive into the specific behaviors of frontline staff [41].

Troubleshooting Guide: Common Implementation Challenges

When implementing a new practice or instrument in a forensic setting, researchers and professionals may encounter several challenges. The following guide, structured using the COM-B model (which is directly linked to the TDF), offers diagnostic questions and solutions informed by the CFIR and TDF [42] [43].

| Observed Problem | Potential Domain of Failure (COM-B / TDF) | Diagnostic Questions to Ask (Informed by TDF & CFIR) | Evidence-Based Solutions & Strategies |

|---|---|---|---|

| Low Staff Engagement | Motivation (Beliefs about Consequences; Professional Role) | • Do staff believe the new intervention is effective? (TDF) • Is the intervention compatible with team culture? (CFIR - Inner Setting) • Do staff see the intervention as part of their professional role? (TDF) | • Share internal pilot data demonstrating effectiveness (CFIR: Evidence Strength) [40]. • Involve formal and informal opinion leaders to champion the cause (CFIR: Engaging) [40]. |

| Inconsistent Use of New Protocol | Opportunity (Environmental Context & Resources; Social Influences) & Capability (Skills) | • Are there sufficient resources (time, equipment) to perform the new protocol? (TDF/CFIR) • Is there consistent feedback and leadership support? (CFIR: Goals & Feedback) Do staff have the requisite skills? (TDF) | • Modify the physical environment or resources to support the behavior [42]. • Implement clear, transparent feedback systems on performance (CFIR) [40]. • Provide skills-based workshops with rehearsal, not just theoretical knowledge [42]. |

| Failure to Sustain Practice Over Time | Motivation (Reinforcement) & Opportunity (Ongoing Support) | • Is use of the new practice rewarded, recognized, or incentivized? (CFIR: Organizational Incentives) • Is there a plan for ongoing coaching and support after initial training? (CFIR: Readiness for Implementation) | • Implement tangible incentives and recognition for sustained use [40]. • Secure long-term funding and infrastructure for ongoing coaching and booster sessions [39]. |

| Pockets of Success, Widespread Failure | Process (Planning; Engaging) & Inner Setting (Structural Characteristics) | • Was the implementation plan tailored to different units/teams? (CFIR: Planning) • Were all key stakeholders, including patients and frontline staff, engaged in the planning process? (CFIR: Engaging) | • Conduct a pre-implementation CFIR-based assessment to identify varying barriers across units [39]. • Create implementation teams that include members from all relevant stakeholder groups [40]. |

Experimental Protocol: A Mixed-Methods Assessment of Implementation Barriers

This protocol outlines a systematic approach for using CFIR and TDF to diagnose implementation challenges for a new analytical instrument in a forensic lab.

Title: A Mixed-Methods Study to Identify Barriers and Facilitators to Implementing [New Instrument/Technique] in a Forensic Research Setting.

1. Objective: To use the CFIR and TDF to comprehensively identify multi-level determinants influencing the implementation of [New Instrument/Technique] to inform the development of a tailored implementation strategy.

2. Methodology:

- Study Design: Convergent parallel mixed-methods design [41] [43].

- Data Collection:

- Qualitative Component:

- Tool: Semi-structured interview and focus group guides, developed by mapping questions to constructs from both the CFIR and TDF [42] [41] [43].

- Participants: Purposive sample of researchers, lab technicians, department managers, and senior leadership.

- Procedure: Conduct and audio-record focus groups and interviews until thematic saturation is reached. Transcribe verbatim.

- Quantitative Component:

- Tool: A survey with closed-ended items developed from the qualitative findings and mapped to CFIR and TDF constructs.

- Participants: Census of all staff involved with the new instrument.

- Procedure: Administer the survey to quantify the prevalence and importance of identified barriers/facilitators.

- Qualitative Component:

3. Data Analysis:

- Qualitative Analysis: Transcripts are analyzed using Framework Analysis, coding data into the pre-defined CFIR and TDF domains. Inductive coding within each domain captures emergent themes [42] [43].

- Quantitative Analysis: Descriptive statistics (e.g., frequencies, means) are calculated for survey responses.

- Integration: A joint display table is created to merge qualitative themes with quantitative frequencies, highlighting convergent and divergent findings. This matrix allows for the prioritization of barriers (e.g., those mentioned frequently in interviews and rated as highly problematic in the survey) [39] [41].

4. Output: A list of prioritized barriers and facilitators, mapped to CFIR and TDF constructs, which directly informs the selection of implementation strategies using a matching tool like the CFIR-ERIC Implementation Strategy Matching Tool.

Workflow and Pathway Visualizations

DOT Script: CFIR-TDF Integrated Implementation Workflow

DOT Script: Troubleshooting Implementation Barriers

The following table details essential "research reagents" and tools for conducting implementation science studies using CFIR and TDF.

| Tool / Resource | Function / Purpose in Implementation Research | Key Application in Forensic Context |

|---|---|---|

| CFIR Technical Assistance Website (cfirguide.org) [39] | Provides the definitive construct definitions, interview questions, and coding guidelines for applying the CFIR. | Serves as the primary reference for designing an evaluation of organizational-level barriers in a secure institution. |

| Theoretical Domains Framework (TDF) [41] | Offers a validated set of domains to investigate individual-level behavioral determinants. | Used to design interviews and surveys probing staff knowledge, skills, and beliefs about a new practice (e.g., de-escalation). |

| CFIR-ERIC Implementation Strategy Matching Tool | Helps researchers select appropriate implementation strategies (e.g., audit & feedback, champions) based on identified CFIR barriers. | Guides the selection of strategies to overcome specific inner setting barriers like a punitive culture or lack of resources. |