Advanced FTIR Sample Preparation for Challenging Paint Samples: Techniques and Troubleshooting

This article provides a comprehensive guide for researchers and scientists on Fourier Transform Infrared (FTIR) spectroscopy sample preparation techniques tailored for difficult paint samples.

Advanced FTIR Sample Preparation for Challenging Paint Samples: Techniques and Troubleshooting

Abstract

This article provides a comprehensive guide for researchers and scientists on Fourier Transform Infrared (FTIR) spectroscopy sample preparation techniques tailored for difficult paint samples. It covers foundational principles of FTIR interaction with complex paint matrices, details specialized methodologies for micro-sampling and substrate challenges, offers solutions for common preparation pitfalls, and validates techniques through comparative analysis with other spectroscopic methods. The guidance is essential for obtaining high-quality, reproducible data from forensic, architectural, artistic, and industrial paint analysis.

Understanding FTIR Fundamentals and Paint Sample Complexity

Fourier Transform Infrared (FTIR) spectroscopy is a powerful analytical technique that measures the interaction of infrared light with matter to provide a unique molecular fingerprint of a sample [1]. For researchers working with complex materials like paint samples, selecting the correct sampling mode is a critical first step that directly impacts the quality and interpretability of the data. FTIR techniques encompass several methods, with transmission and reflectance (including Attenuated Total Reflectance, or ATR) being the most fundamental and widely used approaches [2]. Each method is tailored to specific sample types and analytical goals, enabling precise characterization of molecular vibrations in organic and inorganic compounds [2]. This guide explores the core principles of these techniques within the context of analyzing challenging paint samples, providing troubleshooting advice and methodological frameworks to address common experimental challenges.

Core Sampling Techniques: A Comparative Analysis

Fundamental Principles and Definitions

Transmission FTIR occurs when infrared light passes completely through a sample, with detected light revealing which frequencies were absorbed by the material [3]. The sample preparation often requires the material to be thinly sliced or mounted in a way that allows light to pass through it [3].

Reflectance FTIR encompasses several techniques where IR light is reflected off the sample surface. The most common reflectance method is Attenuated Total Reflectance (ATR), which operates on the principles of total internal reflection [1]. When the angle of a radiation beam entering a crystal surpasses the critical angle, the radiation beam experiences total internal reflection at the crystal surface [1]. However, when a sample is placed in contact with this crystal, the IR beam loses energy at wavelengths where the sample absorbs, creating an attenuated signal that forms the spectrum [1].

Comparative Technical Specifications

Table 1: Comparison of Key FTIR Sampling Techniques for Paint Analysis

| Parameter | Transmission | ATR | Diffuse Reflection |

|---|---|---|---|

| Sample Preparation | Requires thin sections (microtoming) [3] | Minimal; little to no preparation [1] [3] | Varies by substrate |

| Information Depth | Entire sample thickness | Surface-sensitive (few microns) [4] | Surface and near-surface |

| Ideal Paint Sample Types | Cross-sections, thin films | Bulk samples, layered surfaces, fragile specimens [5] | Powders, rough surfaces |

| Data Processing | Standard absorbance | ATR correction (wavelength-dependent penetration) [4] | Kubelka-Munk conversion required [6] [4] |

| Spatial Resolution | Limited by aperture size | Enhanced with germanium crystals [3] | Limited |

| Quantitative Accuracy | High with proper pathlength | Good with pressure control | Moderate with proper standards |

Technique Selection Workflow

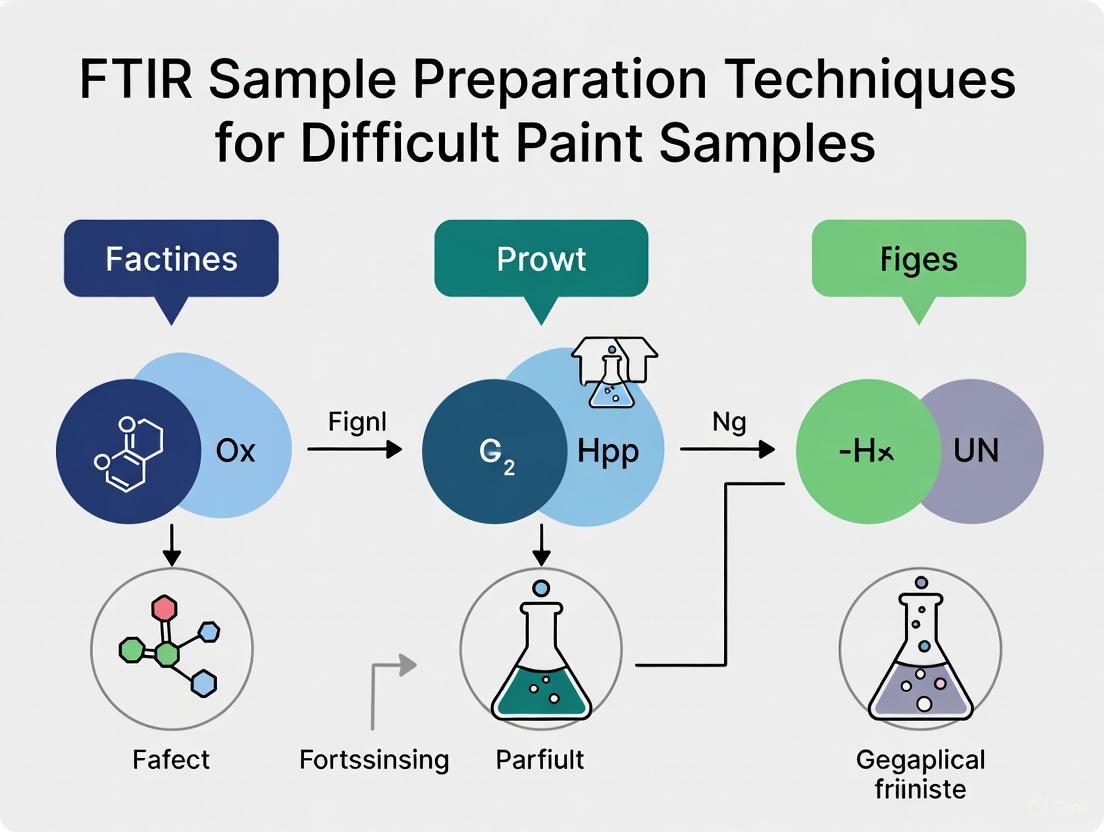

The following diagram illustrates the decision-making process for selecting the appropriate FTIR technique when analyzing paint samples:

Troubleshooting Guides and FAQs

Common Experimental Problems and Solutions

Table 2: Troubleshooting Common FTIR Issues with Paint Samples

| Problem | Possible Causes | Solutions |

|---|---|---|

| Noisy Spectra | Instrument vibrations [6], insufficient scans, dirty optics | Isolate instrument from pumps/lab activity [6] [4], increase scans, clean accessories |

| Negative Peaks | Dirty ATR crystal during background collection [6] [4] | Clean crystal with appropriate solvent, collect new background [6] [4] |

| Distorted Baselines | Sample scattering, improper background, fluorescence | Apply baseline correction, ensure proper sample contact, check sample thickness |

| Spectral Distortion in Diffuse Reflection | Processing in absorbance instead of Kubelka-Munk units [6] [4] | Convert to Kubelka-Munk units for accurate representation [6] [4] |

| Surface vs Bulk Composition Differences | Plasticizer migration, surface oxidation, additives [6] [4] | Analyze both surface and freshly cut interior [6] [4] |

| Weak Absorbance Signals | Poor sample contact with ATR crystal, insufficient pressure | Increase pressure, use uniform pressure application, check crystal cleanliness |

| Substrate Interference | Paint sample too thin, substrate signals dominating | Remove sample from substrate if possible, use background subtraction, optimize sample preparation |

Frequently Asked Questions

Q1: Why does my ATR spectrum look different from a transmission spectrum of the same paint sample?

ATR spectra are wavelength-dependent due to the depth of penetration being proportional to the wavelength, which amplifies higher wavenumber peaks compared to transmission spectra. Most FTIR software includes ATR correction algorithms that apply a wavelength-dependent correction to make ATR spectra more comparable to traditional transmission spectra [4].

Q2: How can I analyze very small paint chips or single-layer fragments?

FTIR microscopy is ideally suited for analyzing small particles and thin coatings [3]. For microscopic samples, use an FTIR microscope equipped with appropriate detectors (LN-MCT for samples below 10µm or TE-MCT for samples below 100µm) and select the proper aperture size to match your sample dimensions [3].

Q3: What should I do when I suspect the surface chemistry of my paint sample doesn't represent the bulk material?

This is a common issue with paints due to surface oxidation or additive migration [4]. For ATR, you can vary the penetration depth by using different ATR crystals with varying refractive indices or different angles of incidence [4]. Alternatively, collect spectra from both the surface and a freshly exposed interior section by cross-sectioning the sample [6] [4].

Q4: How can I analyze paint samples that are firmly adhered to difficult substrates?

ATR-FTIR is particularly valuable for analyzing paints on substrates as it can often be applied directly to the surface without separation [5]. However, with porous substrates, sampling can be complicated and may hamper comparative studies [5]. In such cases, FTIR microscopy with aperture control can help isolate the paint signal from the substrate interference [3].

The Researcher's Toolkit: Essential Materials for FTIR Paint Analysis

Table 3: Essential Research Reagents and Materials for FTIR Paint Analysis

| Item | Function/Application | Technical Notes |

|---|---|---|

| ATR Crystals (Diamond, Germanium, ZnSe) | Surface measurement via internal reflection [1] | Germanium offers highest resolution (4x improvement) [3]; Diamond is most durable |

| Microtome | Thin sectioning for transmission analysis | Essential for creating cross-sections of paint layers |

| Pressure Clamp | Ensures optimal sample-crystal contact | Uniform pressure is critical for reproducible ATR results |

| Cleaning Solvents (Isopropanol, acetone) | Crystal cleaning between measurements | Prevents cross-contamination and negative peaks [6] |

| Silver Chloride Powder | Embedding medium for microtoming | Creates blocks for cutting paint samples [7] |

| FTIR Microscopy Accessories | Analyzing small particles and inclusions | Apertures (knife-edge preferred) define analysis area [3] |

| Background Reference Materials | For proper instrument calibration | Clean crystal surface or appropriate blank |

| Xylose-3-13C | Xylose-3-13C|13C Labeled Isotope|RUO | Xylose-3-13C is a 13C-labeled monosaccharide for research. This product is for Research Use Only (RUO). Not for diagnostic or personal use. |

| SphK1-IN-1 | SphK1-IN-1 | Potent Sphingosine Kinase 1 Inhibitor | SphK1-IN-1 is a potent and selective SPHK1 inhibitor for cancer, fibrosis, and inflammation research. This product is for Research Use Only and not for human or diagnostic use. |

Advanced Methodologies and Workflows

Experimental Protocol: Multi-Layer Paint Analysis Using FTIR Microscopy

For complex paint samples with multiple layers, follow this detailed protocol:

Sample Preparation: Embed a cross-section of the paint sample in a silver chloride powder block under subdued light to prevent degradation [7]. Alternatively, use a microtome to create thin cross-sections approximately 10-20µm thick for transmission analysis.

Instrument Setup: Configure the FTIR microscope with an appropriate detector based on spot size requirements: DLaTGS for >50µm, TE-MCT for >10µm, or LN-MCT for >5µm analysis areas [3]. Select knife-edge apertures for precise region selection [3].

Data Collection:

- For ATR microscopy: Use a germanium crystal for highest spatial resolution [3].

- For transmission: Ensure sample thickness allows sufficient IR transmission.

- Collect background spectra immediately before sample analysis.

Spectral Processing:

- Apply ATR correction when using ATR mode.

- Use baseline correction to compensate for scattering effects.

- Employ second derivatives to resolve overlapping bands in complex mixtures.

Data Interpretation: Combine FTIR data with chemometric tools like Principal Component Analysis (PCA) for objective classification and discrimination of similar paint samples [5].

Experimental Workflow for Forensic Paint Analysis

The following workflow outlines a comprehensive approach for analyzing forensic paint samples using FTIR spectroscopy:

This systematic approach has been successfully demonstrated in forensic applications, where ATR-FTIR combined with PCA achieved 100% discriminating power for differentiating red spray paints from various manufacturers [5]. The non-destructive nature of ATR-FTIR allows for subsequent analysis using other techniques, preserving valuable evidence [5].

For researchers analyzing difficult paint samples, understanding these core principles of transmission versus reflectance modes enables appropriate technique selection and troubleshooting. The integration of FTIR data with chemometric analysis continues to expand the capabilities of this versatile analytical method in material characterization and forensic investigation.

Technical Support Center

This technical support center provides troubleshooting guides and frequently asked questions (FAQs) for researchers using Fourier Transform Infrared (FTIR) spectroscopy to analyze complex paint samples. Paint is a challenging matrix consisting of binders, pigments, and additives, each presenting specific analytical hurdles.

Frequently Asked Questions (FAQs)

FAQ 1: My FTIR spectrum for a paint sample has noisy, uninterpretable data. What could be causing this? Noisy spectra often result from physical vibrations affecting the highly sensitive FTIR spectrometer. Ensure your instrument is placed on a stable, vibration-free surface away from laboratory equipment like pumps or heavy foot traffic. [6]

FAQ 2: I am seeing strange negative peaks in my ATR-FTIR spectrum of a paint film. How can I resolve this? Negative absorbance peaks are a classic indicator of a contaminated ATR crystal. This occurs when a background scan is taken on a clean crystal, but the sample itself leaves a residue, causing the system to "over-subtract." The solution is to thoroughly clean the ATR crystal with an appropriate solvent and acquire a fresh background measurement. [6]

FAQ 3: The FTIR spectrum from the surface of a plastic paint sample looks different from its interior. Why? You are likely observing a surface versus bulk effect. Surface chemistry can differ from the bulk material due to factors like surface oxidation, migration of additives, or environmental weathering. For accurate analysis, compare spectra from both the surface and a freshly cut interior sample. [6]

FAQ 4: When should I use Kubelka-Munk units instead of Absorbance for my paint data? For diffuse reflection measurements (DRIFTS), processing data in absorbance units can distort the spectra. Converting to Kubelka-Munk units is essential as it provides a more accurate representation for quantitative analysis of powdered or rough-surface paint samples. [6] [8]

FAQ 5: My paint sample is too valuable to damage. Are there non-destructive FTIR options? Yes. Traditional ATR requires contact, but FTIR reflectance spectroscopy offers a non-contact, non-destructive method. Using an external reflection accessory, you can analyze paints on valuable artworks or historical objects without any physical contact or sample removal. [9] [10] [11]

Troubleshooting Guides

Problem: Spectral Overlap and Misidentification of Paint Components

Paint is a complex mixture, and its FTIR spectrum is a superposition of signals from all components, leading to potential misidentification.

- Root Cause: Spectral features from binders, pigments, and additives can overlap, obscuring characteristic peaks. For example, a 2025 study on ship paints found that acrylate- and rosin-based paints were frequently misclassified as alkyd or urethane when relying solely on spectral library matching. [12]

- Solution: Employ an integrated analytical approach.

- Cross-verify with elemental analysis: Use Energy Dispersive X-ray Spectroscopy (EDS) to identify inorganic pigments (e.g., Ti from TiO₂, Zn from ZnO) and fillers (e.g., Ca from CaCO₃). The elemental profile helps confirm the paint type. [12]

- Consult reference data: Use published reference data that combines FTIR spectra with elemental profiles for known paint types. [12]

- Leverage far-IR spectroscopy: Many inorganic pigments have weak or no features in the standard mid-IR range. Extending analysis into the far-IR region (e.g., 1800 to 100 cmâ»Â¹) can reveal strong, characteristic peaks for pigments like Cadmium Yellow (absorption at 275 cmâ»Â¹) and Titanium White. [9]

Problem: Challenges in Quantitative Analysis of Pigment-Binder Ratios

It is difficult to move from qualitative identification to reliable quantification of component ratios in a paint mixture.

- Root Cause: The area of an FTIR spectral band is proportional to the concentration of the chemical group it represents, but this relationship must be calibrated. Incorrect baselines or sample preparation inconsistencies lead to poor quantification. [13]

- Solution: Develop a method based on calibration curves using reference samples. [13]

- Prepare Calibration Standards: Create a series of mock-up paints with known, varying ratios of your pigment and binder (e.g., from 1:1 to 1:10, w/w). [13]

- Acquire Spectra: Analyze each standard using ATR-FTIR or Raman spectroscopy.

- Define Signature Peaks: Identify a characteristic, isolated absorption band for each component (e.g., the C=O stretch of an ester in a binder at ~1720 cmâ»Â¹, or the Cr-O vibration of chromium oxide green pigment at 547-483 cmâ»Â¹). [13]

- Generate a Calibration Plot: Integrate the area of the chosen spectral bands and plot them against the known concentration. The resulting straight line (y = mx) serves as your calibration curve. [13]

- Analyze Unknowns: Measure your unknown sample, integrate the same spectral bands, and use the calibration curve to determine its concentration.

Experimental Protocols

Detailed Methodology: Quantitative Analysis of Binders and Inorganic Pigments

This protocol, adapted from a published study, details the steps for quantifying components in paint samples using ATR-FTIR spectroscopy. [13]

1. Principle The area of a specific IR absorption band is directly proportional to the concentration of the chemical group responsible for that band. By creating a calibration curve with samples of known concentration, the relative concentrations of pigments and binders in an unknown sample can be determined. [13]

2. Research Reagent Solutions and Materials

| Item | Function in the Experiment |

|---|---|

| Pure Inorganic Pigments (e.g., PG18, PB29, PY37) | Provides reference spectra and for creating calibration standards. [13] |

| Pure Binder Resins (e.g., Acrylic, Alkyd) | Provides reference spectra and for creating calibration standards. [13] |

| Potassium Bromide (KBr) | An IR-transparent matrix used for diluting samples for transmission FTIR (not always needed for ATR). [14] |

| ATR-FTIR Spectrometer | The core instrument, equipped with a diamond or zinc selenide ATR crystal. [15] |

| Mortar and Pestle / Wig-L-Bug Grinder | For grinding and homogenizing solid samples to a fine, uniform powder (<40 µm). [8] |

3. Step-by-Step Procedure

- Step 1: Qualitative Characterization

- Analyze the pure pigments and binders with ATR-FTIR to identify their characteristic absorption bands for use as quantitative signatures. [13]

- Step 2: Prepare Calibration Samples

- Prepare a series of mock-up paints with precise, known pigment-to-binder ratios (P/BM) by weight. Ensure thorough mixing and homogeneity. [13]

- Step 3: Acquire Spectra of Standards

- Step 4: Generate Calibration Curves

- For each standard spectrum, integrate the area of the pre-defined characteristic absorption band for the pigment and the binder.

- Plot the integrated band area against the known concentration for each standard.

- Perform a linear regression to obtain the calibration equation. [13]

- Step 5: Analyze Unknown Paint Sample

- Prepare the unknown paint sample in the same manner as the standards (e.g., grinding if solid).

- Acquire its ATR-FTIR spectrum and integrate the same characteristic bands.

- Use the calibration equation to calculate the concentration of the components in the unknown sample. [13]

The workflow for this quantitative analysis is summarized in the following diagram:

FTIR Techniques for Different Paint Sample Types

Choosing the correct sampling technique is critical for success. The table below compares the primary methods.

| Technique | Principle | Best For Paint Samples | Key Consideration |

|---|---|---|---|

| ATR [15] | IR light penetrates a few microns into the sample in contact with a crystal. | Most solid and liquid paints; minimal sample prep. [14] [15] | Requires good crystal contact; surface analysis only. |

| Transmission [15] | IR light passes through the entire sample. | Polymer films; analysis of bulk composition. [15] | Requires extensive sample prep (e.g., KBr pellets). [14] |

| DRIFTS [8] | IR light is scattered diffusely by a powdered sample. | Powders, rough surfaces; quantitative analysis. [8] | Requires fine grinding and dilution in KBr. [8] |

| External Reflectance [9] | IR light is reflected off the sample surface without contact. | Valuables/artworks; non-destructive in-situ analysis. [9] [10] | May require Kramers-Kronig transformation of raw data. [9] |

Decision Workflow for Paint Analysis

To select the right analytical path, follow this workflow:

Core Challenges in FTIR Analysis of Paint Samples

The analysis of paint samples via Fourier Transform Infrared (FTIR) spectroscopy presents a unique set of challenges for researchers. These complex, multi-component systems require careful preparation and analysis to generate reliable data. The primary difficulties stem from their intrinsic layered structure, complex composition, and interactions with measurement substrates.

Multi-layered Structure

Automotive and industrial paints are typically composed of multiple layers (e.g., primer, basecoat, clearcoat), each with a specific function [16]. This layered structure is a key forensic identifier, as the sequence and composition are often specific to a manufacturer and model year [16]. However, for analytical purposes, this makes obtaining pure spectra from individual layers without cross-contamination a significant technical challenge. The layers are often micro-sized and physically bonded, making separation with a scalpel difficult and prone to mixing [16].

Complex Composition: Inorganic Fillers and Pigments

Paints are complex mixtures of organic polymers (binders, resins) and inorganic compounds (pigments, fillers) [16]. Common inorganic components identified through analytical techniques include:

- Pigments: TiO₂ (rutile, anatase), ZnO, Fe₃O₄.

- Mineral Fillers: Kaolinite, talc, pyrophyllite.

- Other Inorganic Fillers: BaSO₄, Al₂(SO₄)₃, Zn₃(PO₄)₂, CaCO₃ [16].

While FTIR is excellent for identifying organic resins like alkyd, acrylic, and epoxy, its ability to speciate inorganic compounds can be complemented by other techniques like Raman microspectrometry (RMS), which provides sharp, unambiguous peaks for many inorganics and metal oxides [16].

Substrate Interference and Optical Artifacts

The choice of optical substrate on which a sample is measured can introduce significant interference.

- Interference Fringes: Substantial refractive index mismatches between the sample and the substrate can lead to undulating baselines, known as interference fringes. These are caused by multiple internal reflections within thin, plane-parallel layers and violate the preconditions of the Beer-Lambert law, distorting the spectrum [17].

- Standing Wave Artifact: In reflection measurements, a strong optical "standing wave" artifact can amplify the absorbance spectrum unevenly, particularly in the high wavenumber regions [18].

- Reflection Losses: Even in transmission mode, subtle optical artifacts related to the reflection losses of different substrate materials can interfere. For comparative studies, it is crucial that all samples are measured on the same substrate type to avoid these systematic variations [18].

Troubleshooting Guides & FAQs

Sample Preparation

Q: How can I effectively analyze the individual layers of a multi-layered paint chip without causing cross-contamination? A: The recommended methodology is to create a polished cross-section of the embedded paint chip.

- Embedding: Hold the paint chip vertically and embed it in a liquid epoxy resin within a mold. Allow the resin to solidify completely [16].

- Polishing: Use a multiple-step polishing process on the cross-sectional surface. Sequentially use sandpapers with increasing fineness (e.g., 200, 800, 1200, 2000, and 2400 mesh) to obtain a smooth surface that reveals the layered structure without destroying it [16].

- Analysis: This polished cross-section is then suitable for direct analysis using techniques like ATR-FTIR imaging and SEM/EDX, which can probe the different layers spatially [16].

Q: My FTIR spectrum of a paint sample shows strange, undulating baselines. What is the cause and how can I fix it? A: This is a classic symptom of interference fringes.

- Cause: These fringes are caused by multiple reflections of the IR beam within a thin, film-like sample or between the sample and the substrate. This occurs due to a large refractive index mismatch and creates a wavy baseline that obscures true absorption bands [17].

- Solution: While spectral subtraction can sometimes mitigate this, a more robust solution is to use correction algorithms based on wave optics. These formalisms can computationally correct the deviations from the Beer-Lambert law and remove the fringe effects, restoring a proper baseline [17].

Instrumentation & Environmental Control

Q: Despite purging, I still see moisture peaks in my spectra. Why does this happen, and how can it be removed? A: Residual moisture is a common problem with two potential causes.

- Cause 1: Fluctuating Humidity. The transient concentration of water vapor in the optical path can fluctuate between the background and sample scans [19].

- Cause 2: HeNe Laser Temperature Fluctuation. Subtle temperature changes in the reference HeNe laser can cause a systematic spectral shift, making traditional spectral subtraction ineffective [19].

- Solution: Advanced post-processing techniques are required. One effective approach is the "Retrieve Moisture-Free" (RMF) method, which uses two-dimensional correlation spectroscopy (2D-COS). This method corrects the spectral shift by matching background and sample scans more precisely and then removes the moisture interference from the resultant absorption spectrum [19].

Q: My FTIR instrument fails during the auto-alignment process. What are the most common causes? A: Auto-alignment failure is frequently linked to two issues [20]:

- A dead or weak HeNe laser: The typical lifetime of a HeNe laser is 5-7 years. A weak laser can lead to intermittent bad scans and high laser gain values (X, Y, R signals above 100, especially at 240).

- Humidity-damaged optics: Potassium Bromide (KBR) optics in the beam splitter, sample port windows, or DTGS detector are water-soluble. Exposure to high humidity can "fog" or "craze" these optics, scattering the light and preventing proper interferogram generation.

Data Acquisition & Interpretation

Q: The peaks in my paint spectrum are saturated. What did I do wrong? A: This is typically a sample preparation error.

- Cause: The sample is too concentrated or too thick. This is a common sample preparation error that leads to detector saturation and clipped peaks, making quantification impossible and distorting band shapes [21].

- Solution: For solid samples, re-prepare the sample using less material or create a thinner cross-section. For liquid samples, dilute the sample to an appropriate concentration [21].

Q: A single analytical technique seems insufficient to fully characterize my paint sample. Is there a better approach? A: Yes. Given the complex mixture of organic and inorganic components in paints, a multi-modal approach is highly recommended [16]. The table below outlines the complementary information provided by different techniques.

Table: A Multi-Modal Approach for Comprehensive Paint Analysis

| Technique | Primary Information Obtained | Role in Paint Analysis |

|---|---|---|

| ATR-FTIR Imaging | Molecular species of organic polymer resins (alkyd, acrylic, epoxy, etc.) and some inorganics; spatial distribution in cross-sections [16]. | Identifies the binder and organic additives. |

| Raman Microspectrometry (RMS) | Molecular species of inorganic pigments (TiO₂, ZnO), mineral fillers (kaolinite, talc), and inorganic fillers (BaSO₄, CaCO₃) [16]. | Identifies key pigments and fillers; provides sharp peaks for inorganics. |

| SEM/EDX | Physical structure, layer thickness, and elemental chemical profiles/compositions [16]. | Reveals layer morphology and elemental composition, supporting molecular data. |

| Optical Microscopy | Number of layers and physical heterogeneity [16]. | Initial visual assessment of the sample's layered structure. |

Experimental Protocols & Workflows

Comprehensive Analysis of Multi-layered Paint Chips

The following workflow, based on a published multi-modal approach, is designed for the detailed characterization of multi-layered paint chips [16].

Workflow for Overcoming Moisture Interference

For labs where environmental control is imperfect, this protocol helps retrieve high-quality spectra from data affected by water vapor [19].

Essential Research Reagent Solutions & Materials

The following table details key materials and their functions in the preparation and analysis of difficult paint samples.

Table: Essential Materials for FTIR Analysis of Paint Samples

| Material/Reagent | Function in Analysis | Key Considerations |

|---|---|---|

| Epoxy Embedding Resin | Used to encapsulate the fragile paint chip, providing mechanical support for cross-sectioning and polishing [16]. | A low-viscosity resin is preferable to fully infiltrate and support the sample. |

| Optical Substrates (e.g., CaFâ‚‚, ZnSe, BaFâ‚‚) | Windows and plates for transmission FTIR measurements. The choice of substrate is critical to minimize interference [18]. | Substrates have different spectral ranges and refractive indices. Use the same substrate type for all comparative studies. |

| Reference Materials (e.g., Rutile, Anatase, BaSOâ‚„, Kaolinite) | Standard materials used as references for ATR-FTIR and Raman spectral libraries to confirm the identity of unknown components in the paint [16]. | Use high-purity, reagent-grade standards for reliable identification. |

| Dry Air or Nitrogen Gas | Used to purge the FTIR instrument's optical path, reducing interference from atmospheric water vapor and COâ‚‚ [21]. | Continuous purging is often necessary in high-humidity environments to obtain clean baselines. |

| Polishing Supplies (Sandpapers) | Used in a sequential multi-step process to create a smooth, undisturbed cross-sectional surface of the embedded paint chip for imaging and spectroscopic analysis [16]. | A gradual progression from coarse (200 mesh) to very fine (2400 mesh) grit is essential to avoid scratches and layer deformation. |

The Critical Role of Sample Thickness and the Beer-Lambert Law

Core Principles: Why Sample Thickness is Non-Negotiable in FTIR

The Beer-Lambert Law (also known as Beer's Law) is the fundamental principle governing quantitative absorption spectroscopy, including Fourier Transform Infrared (FTIR) spectroscopy. It states that the absorbance (A) of light by a sample is directly proportional to the concentration (c) of the absorbing species and the path length (L) the light travels through the sample [22] [23]. The law is formally expressed as:

A = εlc

Where:

- A is the measured absorbance (a dimensionless quantity).

- ε is the molar absorptivity (a sample-dependent constant, in L·molâ»Â¹Â·cmâ»Â¹).

- l is the optical path length, which corresponds to sample thickness (in cm).

- c is the concentration of the absorbing species (in mol·Lâ»Â¹).

For FTIR analysis of homogeneous solid samples like paint films, the "concentration" of the molecular bonds is effectively fixed. Therefore, sample thickness (l) becomes the critical, user-controlled variable that directly determines the intensity of the absorption bands in the spectrum [24].

The Consequences of Excessive Thickness

If a sample is too thick, the absorbance values can become excessively high. According to the Beer-Lambert Law, an absorbance of 1 corresponds to 10% transmittance, an absorbance of 2 to 1% transmittance, and so on [22]. When absorbance exceeds approximately 1.2 AU, the instrumental response can become non-linear [24]. This leads to:

- Flattened (saturated) peak tops, where the peaks appear to be cut off.

- Excessive noise in the spectrum.

- Obscured peak locations and heights, leading to poor library search results and a loss of quantitative information [24].

The ideal thickness for a transmission FTIR sample is typically in the range of 10–50 µm to ensure absorbance values remain within a usable linear range [24].

Table 1: Relationship Between Absorbance, Transmittance, and Spectral Quality

| Absorbance (A) | % Transmittance | Impact on Spectral Quality |

|---|---|---|

| 0 - 1.2 | 100% - ~6% | Ideal Range: Linear detector response; accurate peak heights and positions. |

| > 1.2 | < ~6% | Non-Linear Range: Peak tops flatten, noise increases, quantitative data becomes erroneous. |

| >> 1.2 | << 1% | Saturation: Peaks are lost; spectrum is useless for identification and quantification. |

Troubleshooting Guide: Common Problems Related to Sample Thickness

Problem 1: Peaks are "cut off" or flattened at the top.

- Explanation: This is a classic sign of excessive sample thickness, leading to total absorption of the infrared light at specific wavelengths. The detector cannot respond to the extreme absorbance, causing the peaks to saturate [24].

- Solution: Re-prepare the sample to make it thinner. For transmission measurements, use a microtome or a compression cell to achieve a thickness below 50 µm. For ATR measurements, ensure firm, uniform pressure is applied to achieve good crystal contact, but note that ATR inherently limits the effective path length.

Problem 2: The spectrum has a very high baseline and low signal-to-noise ratio.

- Explanation: A high baseline can be caused by light scattering, which is often a result of a rough or uneven sample surface. An overly thick sample can exacerbate this issue and also reduce the total energy reaching the detector, resulting in a noisy spectrum [4].

- Solution: For transmission, ensure the sample is not only thin but also has parallel, smooth surfaces. For ATR, clean the crystal thoroughly and ensure the sample makes homogeneous contact. Re-prepare the sample with a smoother surface finish.

Problem 3: The obtained spectrum does not match the library reference.

- Explanation: Saturated peaks (from excessive thickness) or distorted band ratios (from optical effects like interference fringes in thin, uniform films) can significantly alter the spectral profile, causing poor matches against reference databases [24] [25].

- Solution: Re-prepare the sample to an ideal thickness. If interference fringes are present (appearing as a sinusoidal wave pattern in the baseline), note that simple cosmetic removal may not address all underlying optical effects [25].

Problem 4: Negative peaks appear in the absorbance spectrum when using ATR.

- Explanation: This is a common issue unrelated to thickness but critical for data quality. It indicates that the ATR crystal was dirty or contaminated when the background measurement was collected. The sample measurement then "subtracts" the contaminant's absorption, creating negative peaks [4].

- Solution: Clean the ATR crystal thoroughly with an appropriate solvent, collect a new background spectrum, and then re-analyze your sample.

Experimental Protocols for Optimal Paint Sample Preparation

Protocol 1: Transmission Analysis with Compression Cell

This method is excellent for flattening and thinning small paint chips.

- Placement: Position a small paint fragment on the center of a KBr or diamond window of the compression cell [24].

- Add KBr Powder: Place a tiny amount of KBr powder next to the sample. This will be used later for collecting a clean background and helps to reduce interference fringing [24].

- Compress: Carefully lower the upper window and apply gentle, firm pressure to compress and flatten the sample. Diamond cells allow for higher compression pressure without breaking [24].

- Background Collection: Collect a background spectrum through the compressed KBr powder spot to account for the substrate properties [24].

- Sample Measurement: Move the cell to position the sample in the beam path and collect the spectrum.

Protocol 2: Microtomy for Cross-Sectional Analysis

This is the gold standard for creating thin, uniform sections, ideal for analyzing individual paint layers.

- Embedding: Place the paint sample on its edge in a small mold. Mix and pour a 5:1 epoxy resin-to-hardener mixture into the mold, covering the sample. Allow it to cure for 24 hours to form a solid "puck" [24].

- Polishing: After demolding, polish the end of the puck to expose the paint sample embedded within [24].

- Sectioning: Clamp the puck into a microtome. Carefully bring it into contact with the blade to remove thin slices, typically 5–10 µm in thickness [24].

- Collection: Lift the thin film slices from the blade with a needle probe.

- Analysis: Position one or more slices on a KBr window or in a compression cell for FTIR analysis. The spectrum should show minimal traces of the epoxy resin [24].

Sample Preparation Workflow for Paint Analysis

Advanced Considerations: The Limits of the Beer-Lambert Law

The Beer-Lambert Law is a powerful but idealized model. Researchers must be aware of its limitations, which are particularly relevant for thin film samples like paints [25] [26].

- Interference Effects: The law does not account for the wave nature of light. When a sample is thin and uniform (like a paint film on an IR-transparent substrate), the light can reflect between the two interfaces, creating constructive and destructive interference. This appears as a sinusoidal "fringe" pattern on the baseline of the spectrum and can distort band shapes and intensities [25].

- Reflection Losses: The classic derivation of the law assumes no light is lost to reflection at the sample surfaces. In reality, any sample with interfaces (e.g., a free-standing film or one on a substrate) will have reflection losses, which are not accounted for in the simple A = εlc formula [26].

- Optical Dispersion: The molar absorptivity (ε) is not a perfect constant. It is intrinsically linked to the refractive index of the material, and both change rapidly across an absorption band—a phenomenon known as dispersion. This can lead to apparent shifts in peak positions when compared to transmission spectra collected under different conditions [26].

Table 2: Essential Materials for FTIR Sample Preparation

| Material / Tool | Function in Sample Prep | Key Considerations |

|---|---|---|

| Diamond Compression Cell | Flattens and thins samples for transmission measurement. | Withstands high pressure; diamond absorption bands must be ratioed out during background collection [24]. |

| KBr Windows | Substrate for placing and analyzing samples in transmission. | Inexpensive but soft and hygroscopic (water-soluble); require careful handling [24]. |

| Microtome | Produces thin, uniform slices of a defined thickness (e.g., 5-10 µm). | Essential for analyzing cross-sections of multi-layer paint samples [24]. |

| ATR Crystal (Diamond/ZnSe) | Enables measurement with minimal sample prep by pressing the sample against a high-refractive-index crystal. | Depth of penetration is limited and wavelength-dependent; good for surface analysis [27] [1]. |

| Epoxy Resin | Used to embed fragile samples for microtomy, providing structural support. | Must be selected for low IR absorption to avoid interfering with the sample's spectrum [24]. |

Frequently Asked Questions (FAQs)

Q1: My paint sample is too brittle to section with a microtome. What can I do? A1: Embedding the sample in an epoxy puck is the standard solution. This provides the necessary structural support to hold the brittle paint together during the sectioning process, allowing for clean, thin slices to be obtained [24].

Q2: Can I use ATR for all my paint samples to avoid thickness issues? A2: ATR is a highly convenient technique that largely bypasses the strict thickness requirements of transmission measurements because the evanescent wave only penetrates a few microns into the sample. However, be aware that ATR spectra can be influenced by surface contamination, and the technique may not be representative of the bulk chemistry if the paint has migrated additives or is stratified [4].

Q3: What is the simplest way to check if my sample is too thick? A3: Examine the strongest peak in your spectrum. If the top of the peak is flat and does not come to a point, it is likely saturated, indicating the sample is too thick. Visually, the ideal spectrum should have all absorption bands with sharp, well-defined peaks, not flattened tops [24].

Q4: Why do I see sine waves (fringes) in my spectrum's baseline? A4: These are interference fringes caused by the wave nature of light. They occur when you have a thin, uniform film acting as a Fabry-Pérot etalon, with light reflecting and interfering between the two parallel surfaces. While algorithms exist to remove them mathematically, it is better to avoid them by preparing the sample with a slightly wedged or non-uniform thickness, or by embedding and sectioning it [25].

FTIR Transmission Principle

Fourier Transform Infrared (FTIR) spectroscopy is a powerful analytical technique that provides a molecular 'fingerprint' of a sample, making it indispensable for identifying and quantifying various materials [28]. The accuracy and reproducibility of FTIR data heavily depend on the sampling technique used and the corresponding sample preparation [29]. The choice of an appropriate sampling method is critical and is dictated by the physical state (solid, liquid, gas) and chemical properties of the sample, as well as the specific information required from the analysis (e.g., surface vs. bulk composition) [29] [30]. For researchers working with complex samples like paints, selecting the correct technique is paramount for obtaining reliable, interpretable data that can support forensic, developmental, or quality control conclusions.

This guide provides a detailed overview of the four major FTIR sampling techniques—Transmission, Attenuated Total Reflectance (ATR), Specular Reflectance, and Diffuse Reflectance. It is structured to serve as a technical support center, complete with troubleshooting guides and FAQs, specifically framed within the context of analyzing difficult paint samples. The content is designed to help researchers and scientists navigate the practical challenges of FTIR spectroscopy, from selecting the right method to solving common experimental problems.

Detailed Technique Breakdown

Transmission FTIR

Transmission is the most traditional and straightforward FTIR technique [30]. It operates on a simple principle: incident infrared light is passed through the sample, and the detector measures the amount of light that is transmitted [29] [30]. The resulting spectrum is a plot of percent transmission versus wavenumber, showing which frequencies of light were absorbed by the sample.

Experimental Protocol for Transmission FTIR: The required sample preparation varies significantly by sample state:

- Solid Paints/Powders: The KBr Pellet method is common. A small amount of powdered sample is mixed with powdered potassium bromide (KBr) and pressed under high pressure into a transparent pellet using a pellet die [29]. A blank KBr pellet is required for a background spectrum. Alternatively, a powdered sample can be sandwiched between two infrared-transparent window plates (e.g., KBr, NaCl) in a demountable cell [29].

- Liquid Samples (e.g., paint solvents): The sample can be injected into a sealed liquid cell with a defined pathlength or sandwiched between two IR-transparent windows in a demountable cell [29].

- Gases: The sample is introduced into a gas cell with a long pathlength, which is often heated to prevent condensation [29].

Advantages and Limitations:

- Advantages: Considered the foundational technique; can provide high-quality data for a wide range of samples [30].

- Limitations: Requires significant sample preparation [29] [30]. KBr is hygroscopic, absorbing atmospheric moisture which can interfere with the spectrum [29]. Solid samples must be finely ground and uniformly dispersed to avoid light scattering, which can lower measured absorbance [29].

Attenuated Total Reflectance (ATR)

ATR has become the dominant sampling technique for solid and liquid analysis due to its minimal sample preparation requirements [29] [30]. It operates on the principle of total internal reflection. An IR beam is directed into a crystal with a high refractive index (the ATR crystal) at a specific angle. When the light reflects internally, an evanescent wave extends beyond the crystal surface into the sample in contact with it. The sample absorbs energy at characteristic frequencies, attenuating the evanescent wave. This attenuated beam is then directed to the detector [29] [28].

Experimental Protocol for ATR-FTIR:

- Collect a Background: Clean the ATR crystal thoroughly with an appropriate solvent and collect a background spectrum with no sample present.

- Apply the Sample: Place the sample in direct, firm contact with the crystal. For solids, a clamping arm is used to apply pressure to ensure good contact [30]. For liquids, a single drop is sufficient.

- Collect the Spectrum: The spectrum is collected directly, typically with no further preparation.

Advantages and Limitations:

- Advantages: Minimal to no sample preparation; non-destructive; ideal for strongly absorbing or thick samples; excellent for analyzing thick or strongly absorbing samples like black rubber [29] [28]. It is highly suitable for paints, plastics, and coatings [28].

- Limitations: The technique is surface-sensitive, with a typical penetration depth of 0.5 to 2 µm [29]. Spectra intensity may vary with the pressure applied and the hardness of the sample. ATR spectra have slightly different intensity ratios across the spectrum compared to transmission and may require a correction for direct library comparison [29].

Specular Reflectance

Specular reflectance is an external reflectance technique used for analyzing smooth, flat surfaces, such as mirrors or coated metals [29] [30]. It follows the law of reflection where the angle of incidence equals the angle of reflection. The technique measures the energy reflected off the surface of a sample, providing information about its refractive index and absorbency [28].

Experimental Protocol for Specular Reflectance:

- Sample Preparation: Little to no sample preparation is required [29]. The sample should have a smooth, flat, and reflective surface.

- Alignment: The accessory must be properly aligned so the incident and reflected beams are at the same angle.

- Data Correction: Specular reflectance spectra can include derivative-like peaks due to the combination of absorption and reflection components. A Kramers-Kronig (K-K) correction is often applied mathematically to eliminate these distortions and produce a spectrum that resembles a transmission spectrum for easier interpretation and library searching [29].

Advantages and Limitations:

- Advantages: Highly sensitive for analyzing thin films (down to angstrom-level thickness) and monolayers on reflective substrates like metal surfaces; non-destructive [29] [28].

- Limitations: Primarily suited for smooth, reflective surfaces. The raw spectra can be difficult to interpret without mathematical correction [29].

Diffuse Reflectance (DRIFTS)

Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS) is designed for analyzing rough-surface solids and powders [29] [30]. Unlike specular reflectance, when light hits a powdered sample, it penetrates the particles, is absorbed, and is then scattered in all directions [29] [28]. This scattered light is collected to generate the spectrum.

Experimental Protocol for DRIFTS:

- Prepare the Sample Cup: Fill the sample cup with a fine powder of the sample, either neat or diluted in an IR-transparent matrix like KBr [29] [28].

- Collect a Background: Collect a background spectrum with the sample cup filled only with the dilution matrix (e.g., KBr).

- Data Processing: The collected spectrum must be converted into Kubelka-Munk (K-M) units rather than absorbance. This correction is essential to produce a spectrum where band intensities are linear with concentration and comparable to transmission spectra [6] [4]. The sample should be finely ground and loosely packed to maximize diffuse reflection [29].

Advantages and Limitations:

- Advantages: Little sample preparation required; no need for pellets or mulls; ideal for intractable powders and highly scattering samples [29] [28].

- Limitations: Quantitative analysis can be difficult as it is highly sensitive to particle size, packing density, and dilution ratio [29]. Incorrectly processing data in absorbance units instead of K-M will severely distort the spectrum [6] [4].

Technique Selection Guide

The following diagram illustrates the decision-making process for selecting the most appropriate FTIR sampling technique, with a focus on paint sample analysis:

Comparative Analysis of Techniques

For a quick comparison, the table below summarizes the key characteristics of the four main FTIR sampling techniques.

Table 1: Comparison of Common FTIR Sampling Techniques

| Technique | Principle | Sample Type | Sample Preparation | Key Advantage | Primary Limitation |

|---|---|---|---|---|---|

| Transmission [29] [30] | Measures light passing through the sample | Solids, liquids, gases | Extensive (e.g., KBr pellets, liquid cells) | Traditional, straightforward method | High sample preparation required; KBr is hygroscopic |

| ATR [29] [30] [28] | Measures attenuation of an evanescent wave from internal reflection | Solids, liquids, viscous pastes | Minimal to none | Minimal preparation; non-destructive; ideal for surfaces | Surface-sensitive; spectrum intensity depends on contact |

| Specular Reflectance [29] [28] | Measures light reflected at an equal angle from a surface | Smooth, flat surfaces (e.g., coated metals) | Minimal | Sensitive to thin films and monolayers | Requires smooth surface; spectra need Kramers-Kronig correction |

| Diffuse Reflectance (DRIFTS) [29] [30] [28] | Measures scattered light from a powdered sample | Powders, rough surfaces | Moderate (grinding, mixing with KBr) | Excellent for powders and scattering solids | Sensitive to particle size/packing; requires Kubelka-Munk correction |

The Scientist's Toolkit: Essential Materials for FTIR

Table 2: Key Research Reagent Solutions for FTIR Sample Preparation

| Material | Function & Application | Notes for Paint Sample Analysis |

|---|---|---|

| Potassium Bromide (KBr) [29] | IR-transparent matrix used for preparing pellets of solid samples in Transmission FTIR. | Hygroscopic; can interfere with samples that have absorption bands in the same regions as water. Not suitable for samples containing chlorides [29]. |

| ATR Crystals (Diamond, ZnSe, Germanium) [29] [30] | The internal reflective element in ATR accessories. | Diamond: Rugged, general-purpose. ZnSe: Excellent throughput but fragile. Germanium: Low penetration depth, good for highly absorbing samples or surface studies [29] [30]. |

| Nujol (Mineral Oil) [29] | A mineral oil used to create a mull for Transmission FTIR when KBr is unsuitable. | Useful for moisture-absorbing samples (e.g., sugars) or inorganic substances. Obscures C-H absorption regions (3000–2800 cmâ»Â¹) [29]. |

| Phosphatase-IN-1 | Phosphatase-IN-1, MF:C16H16Cl2FNO2, MW:344.2 g/mol | Chemical Reagent |

| Erap2-IN-1 | Erap2-IN-1, MF:C20H21F3N2O5S, MW:458.5 g/mol | Chemical Reagent |

Troubleshooting Guides and FAQs

Common Problems and Solutions

Problem: Negative peaks or distorted baselines in ATR spectra.

Problem: Surface spectrum of a paint film does not match the bulk spectrum.

- Cause & Solution: Surface vs. Bulk Chemistry. Plasticizers can migrate, or the surface can oxidize, making it chemically different from the bulk [6] [4]. For ATR, try analyzing a freshly cut interior surface. Alternatively, use different ATR crystals (e.g., Germanium) to vary the penetration depth and probe different sample layers [4].

Problem: Peaks in DRIFTS spectrum look saturated and distorted.

Problem: Spectrum is noisy or has strange, sharp features.

- Cause & Solution: Instrument Vibration. FTIR spectrometers are highly sensitive to physical disturbances from nearby equipment or lab activity [6]. Ensure the instrument is on a stable, vibration-free bench. Check for nearby pumps or other sources of vibration.

Problem: FTIR fails to scan or alignment fails.

Frequently Asked Questions (FAQs)

Q1: Why might ATR be the preferred technique for analyzing paint samples in forensic casework? ATR is often preferred because it is rapid, non-destructive, and requires minimal to no sample preparation [5]. This is critical in forensic contexts where sample preservation is necessary for further analysis by other techniques. It also allows for the direct analysis of paint traces on various substrates without the need for complex separation [5].

Q2: What are the key data processing corrections needed for reflectance techniques?

- Specular Reflectance: Often requires a Kramers-Kronig (K-K) correction to remove derivative-shaped distortions and generate a transmission-like spectrum for library searching [29].

- Diffuse Reflectance (DRIFTS): Must be converted to Kubelka-Munk (K-M) units to ensure band intensities are correct and comparable to transmission libraries [29] [4].

Q3: How accurate are the peak positions in an FTIR spectrum? For well-resolved, non-saturated peaks, the wavenumber accuracy is typically within 1.1 cmâ»Â¹ at a spectral resolution of 4 cmâ»Â¹ or higher [32]. Previous estimates that suggested variations of up to 10 cmâ»Â¹ between instruments are now considered gross overestimates [32].

Q4: Can FTIR analysis definitively prove a fault in paint application? Yes. In one case study, FTIR analysis identified that hollow core doors were primed with oil-based paint and finished with latex paint. Since latex does not properly adhere to oil-based paint without specific preparation, the FTIR data conclusively proved that faulty application methods led to peeling, supporting an insurance claim [33].

Step-by-Step Sample Preparation Methods for Diverse Paint Types

Troubleshooting Guides

KBr Pellet Preparation

Problem: Pellet is cloudy or cracked, leading to poor spectral quality.

- Cause 1: KBr powder or sample is absorbing moisture from the atmosphere.

- Cause 2: Insufficient grinding of the sample-KBr mixture.

- Cause 3: Incorrect sample-to-KBr ratio.

- Cause 4: Uneven or incorrect pressure applied during pressing.

- Solution: Use a consistent, controlled pressure with a hydraulic pellet press. An integrated pressure gauge helps ensure reproducibility [34].

Problem: Weak or noisy spectra.

- Cause 1: Pellet is too thick, causing total absorbance, or too thin.

- Solution: Aim for a pellet that is transparent and appropriately thin. Excessively thick pellets require remaking with a more diluted sample [15].

- Cause 2: Sample concentration is too low.

- Solution: Slightly increase the proportion of sample in the KBr mixture, ensuring it stays within the optimal range for quantitative analysis [34].

Microtomy for Thin Sections

Problem: The ribbon does not form or is compressed.

- Cause 1: Knife clearance angle is incorrect.

- Solution: Adjust the knife to the proper clearance angle as per the microtome manufacturer's instructions [36].

- Cause 2: The embedding medium (e.g., paraffin) is too hard or too soft, or the blade is dull.

- Solution: For hard wax, try warming the block slightly by breathing on it. For soft wax, ice the block. Move to a sharp section of the blade or replace the blade entirely [36].

Problem: Sections have thick and thin areas or knife lines (tears).

- Cause 1: Something is loose on the microtome, or the sample tissue is very dense.

- Solution: Tighten all knobs and levers on the microtome. For dense tissue, icing the block can help [36].

- Cause 2: Nicks in the knife edge.

- Solution: Move the blade to a fresh, undamaged section or replace the blade. Hard particles in the sample, like calcium or pigments, can also cause this [36].

Problem: Sections curl or roll up.

- Cause: Knife is too dull or too sharp, section is too thick, or embedding medium is too soft.

- Solution: Use a blade with appropriate sharpness, make a thinner section, or use a lower melting point (softer) wax [36].

General Transmission FTIR Issues

Problem: Bands from water vapor or COâ‚‚ in the spectrum.

- Cause: Atmospheric interference within the instrument or sample compartment.

Problem: Negative absorbance peaks or a distorted baseline.

- Cause: A contaminated accessory (e.g., a dirty ATR crystal) was used for the background scan, or the background has changed.

Problem: Spectral fringing (interference patterns).

- Cause: This is common with very thin samples, such as those prepared by microtomy, where internal reflections can occur.

- Solution: The phenomenon can be remedied through appropriate data preprocessing of the spectral line map [38].

Frequently Asked Questions (FAQs)

Q1: Why is KBr used for pellet preparation in Transmission FTIR? KBr is used because it is transparent to a wide range of infrared radiation. When subjected to high pressure, it becomes plastic and forms a clear pellet that allows IR light to pass through, with the analyte dispersed evenly within it [15] [34].

Q2: What is the ideal thickness for a solid sample in Transmission FTIR? For reliable results, the sample should be very thin, typically less than 15 microns. If the sample is too thick, too much IR light will be absorbed, leading to poor spectral quality with peaks that are not easily distinguished (total absorbance) [15].

Q3: My paint sample is multi-layered and very small (<1 mm). What is the best preparation method? For small, multi-layered paint chips, microtomy is the recommended technique. Using an ultramicrotome, you can cross-section minute paint chips to expose the different layers for analysis via transmission infrared microscopy, which is essential for forensic and materials analysis [38].

Q4: How can I avoid cross-contamination between samples when using a KBr pellet press? Thoroughly clean all equipment, including the mortar and pestle, die, and presses, between each sample preparation. Using disposable gloves and working in a clean environment also helps prevent cross-contamination [35].

Q5: What are the key advantages of microtomy over other sample preparation methods for paints? Microtomy allows for the precise cross-sectioning of multi-layered paint samples, enabling the analysis of individual layers. This is crucial for identifying the sequence and composition of coatings, which is a common requirement in forensic paint analysis and coatings characterization [38].

Experimental Protocols

Detailed Methodology: KBr Pellet Preparation for Paint Analysis

This protocol is designed for analyzing solid paint samples to create a "chemical fingerprint" of the polymeric binders and additives [15] [39].

- Preparation of KBr Powder: Place a sufficient quantity of potassium bromide (KBr) powder in a clean mortar. Dry it in an oven at approximately 110°C for 1-2 hours to remove absorbed water. Store the dried KBr in a desiccator to keep it dry [34].

- Sample Preparation: Scrape a small amount of the paint sample (approximately 0.5-1.0 mg) into a separate mortar. Grind it thoroughly to a fine powder.

- Mixing: Combine the ground paint sample with 100-200 mg of dried KBr powder. This achieves a sample concentration of about 0.5% to 1%. Grind the mixture together for at least 60 seconds to ensure a homogeneous, fine mixture.

- Loading the Die: Transfer the mixture into a clean pellet die assembly, ensuring it is spread evenly.

- Pressing the Pellet: Place the die in a hydraulic pellet press. Apply a pressure of approximately 8-10 tons for 1-2 minutes under a vacuum to eliminate air and moisture, which can cause cloudiness or scattering.

- Pellet Recovery: Carefully remove the clear pellet from the die and mount it in a suitable pellet holder.

- FTIR Analysis: Immediately place the holder in the FTIR spectrometer and collect the spectrum.

Detailed Methodology: Microtomy of Multi-Layered Paint Chips

This protocol is adapted for preparing thin sections of paint chips for high-resolution layer-by-layer analysis [38] [36].

- Embedding: To provide support during sectioning, embed the small paint chip in a suitable resin block.

- Trimming: Use a razor blade to trim the resin block, ensuring the paint chip is exposed and the block face is parallel to the knife edge. This is critical for forming a straight ribbon.

- Sectioning: Mount the block securely in the microtome. Using a sharp glass or diamond knife, cut thin sections with a thickness setting between 1 and 10 microns. For FTIR analysis, thinner sections are generally better to avoid total absorbance.

- Ribbon Handling: As sections are cut, they should form a ribbon. Gently lift the ribbon with a soft brush or tweezers.

- Mounting: Float the ribbon onto a water bath to remove wrinkles. Carefully pick up the sections and place them on a KBr or NaCl window suitable for transmission FTIR.

- Drying: Allow the mounted sections to dry completely before spectral acquisition.

- FTIR Imaging: Analyze the thin section using an FTIR microscope in transmission mode. The different layers can be mapped to extract individual spectra for each coating layer.

Data Presentation

Table 1: Troubleshooting Common FTIR Sample Preparation Problems

| Problem | Cause | Solution |

|---|---|---|

| Cloudy KBr Pellet | Moisture absorption, insufficient grinding | Dry KBr, grind finely, work in low humidity [34] [35] |

| Weak Spectral Signal | Sample too dilute, pellet too thick | Increase sample concentration (0.2-1%), make thinner pellet [15] [34] |

| No Ribbon Formation (Microtomy) | Wrong knife angle, wax too hard | Adjust knife angle, warm block slightly [36] |

| Section Compression | Dull blade, wax too soft | Change blade or blade area, ice the block [36] |

| Atmospheric Peaks (Hâ‚‚O, COâ‚‚) | Insufficient instrument purging | Purge instrument with dry air/nitrogen [37] [35] |

Table 2: Essential Research Reagent Solutions for Transmission FTIR

| Item | Function | Application Note |

|---|---|---|

| Potassium Bromide (KBr) | Matrix material; transparent to IR light | Must be dry and spectroscopic grade. Forms pellets for solid sample analysis [15] [34]. |

| Hydraulic Pellet Press | Applies high, uniform pressure to form KBr pellets | Integrated pressure gauge ensures reproducible pellet quality [34]. |

| Microtome | Cuts thin, uniform sections of samples | Essential for cross-sectioning multi-layered materials like paint chips [38] [36]. |

| Diamond Knife | Provides a sharp, durable edge for microtomy | Used with an ultramicrotome for sectioning very hard or small samples [38]. |

| Mortar and Pestle | Grinds and mixes solid samples with KBr | Ensures a homogeneous and fine particle size for clear pellets [34] [35]. |

Workflow and Relationship Diagrams

Thin Sample Preparation Workflow

FTIR Problem-Solving Logic

Attenuated Total Reflectance Fourier-Transform Infrared (ATR-FTIR) spectroscopy has revolutionized molecular analysis of challenging samples, particularly in forensic paint examination. This technique enables researchers to obtain high-quality infrared spectra with minimal sample preparation, preserving evidence integrity while delivering robust chemical identification. For researchers dealing with difficult paint samples, ATR-FTIR provides a non-destructive pathway to characterize chemical composition directly from various substrates without complex extraction procedures.

Technical Foundation: Why ATR-FTIR Excels with Minimal Preparation

ATR-FTIR operates on the principle of total internal reflection. An infrared beam travels through an internal reflective element (IRE) crystal with a high refractive index and reflects off the internal surface in contact with the sample. During each reflection, an evanescent wave extends beyond the crystal surface into the sample, typically penetrating 0.5-2 micrometers, where it is selectively absorbed by the sample's molecular components [40]. The attenuated beam is then directed to the detector, generating an infrared absorption spectrum [1].

This mechanism provides significant advantages for analyzing difficult paint samples:

- Minimal sample preparation required compared to transmission techniques [30]

- Non-destructive analysis preserves sample integrity for additional testing [5]

- Direct substrate analysis enables examination of paints on various surfaces [5]

- Superior surface sensitivity ideal for layered paint samples [40]

Experimental Protocol: Forensic Analysis of Automotive Paint Samples

The following methodology, adapted from validated forensic protocols, ensures reliable analysis of automotive paint samples with minimal preparation [41]:

Sample Collection and Preparation

- Sample Collection: Collect paint chips or fragments from the scene using clean tweezers. For direct substrate analysis, examine painted surfaces without removal when possible.

- Visual Inspection: Document sample color, layers, and physical characteristics using microscopic examination.

- Surface Cleaning: Gently remove surface contaminants using a soft brush or compressed air. Avoid solvents unless necessary and document their use.

- Sample Positioning: For loose chips, select a representative area with minimal surface degradation. Ensure flat surfaces for optimal crystal contact.

Instrumentation and Data Acquisition

- ATR Crystal Selection: Diamond ATR crystals are recommended for paint analysis due to their durability and chemical resistance [40].

- Background Scan: Collect background spectrum with no sample contacting the crystal.

- Sample Measurement: Apply consistent pressure via the ATR clamp mechanism to ensure optimal crystal contact.

- Spectral Acquisition: Collect spectra typically over 4000-400 cmâ»Â¹ range with 4 cmâ»Â¹ resolution and 32-64 scans [41].

- Replicate Measurements: Analyze multiple areas of heterogeneous samples to ensure representative sampling.

Data Processing and Analysis

- Spectral Correction: Apply atmospheric suppression and baseline correction algorithms.

- Library Matching: Compare acquired spectra against reference databases of paint formulations.

- Chemometric Analysis: Implement multivariate statistics (PCA, PLS-DA) for discrimination of similar samples [41].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 1: Essential Materials for ATR-FTIR Analysis of Paint Samples

| Item | Function | Application Notes |

|---|---|---|

| Diamond ATR Crystal | Internal Reflection Element (IRE) | Virtually indestructible; ideal for hard paint samples; chemical resistant [40]. |

| ZnSe ATR Crystal | Alternative IRE | Excellent throughput; avoid with acidic samples and hard particles [29]. |

| Germanium ATR Crystal | IRE for high refractive index samples | Very low penetration depth; good for surface studies [29]. |

| High-Purity Solvents | Sample cleaning | Remove contaminants without dissolving paint components. |

| Reference Paint Databases | Spectral comparison | PDQ and other databases for chemical identification [41]. |

| Soft Cleaning Supplies | Crystal maintenance | Isopropyl alcohol and lint-free wipes for crystal cleaning [6]. |

| 7Ethanol-10NH2-11F-Camptothecin | 7Ethanol-10NH2-11F-Camptothecin, MF:C21H18FN3O5, MW:411.4 g/mol | Chemical Reagent |

| Topoisomerase I inhibitor 8 | Topoisomerase I inhibitor 8, MF:C24H21FN2O4, MW:420.4 g/mol | Chemical Reagent |

Troubleshooting Guide: Addressing Common Experimental Challenges

Table 2: Common ATR-FTIR Issues and Solutions for Paint Analysis

| Problem | Possible Cause | Solution | Prevention |

|---|---|---|---|

| Noisy Spectra | Insufficient sample contact, detector issues, insufficient scans | Increase clamp pressure, check detector function, increase scan number | Ensure sample flatness, verify instrument alignment |

| Negative Peaks | Contaminated ATR crystal | Clean crystal with appropriate solvents, recollect background [6] | Clean crystal before each use, check background regularly |

| Distorted Baselines | Incomplete background collection, light scattering | Recollect background, ensure proper sample contact | Allow instrument to warm up, verify background quality |

| Weak Absorbance | Inadequate sample contact, weathered samples | Increase applied pressure, analyze less degraded areas | Optimize clamp pressure, sample from protected areas |

| Spectral Artifacts | Instrument vibration, substrate interference | Isinstrument from vibrations, use subtraction techniques | Place on stable surface, analyze substrate separately |

| Poor Reproducibility | Inconsistent pressure, sample heterogeneity | Use calibrated pressure arm, analyze multiple spots | Standardize pressure application, sample multiple areas |

Frequently Asked Questions (FAQs)

Q1: Can ATR-FTIR analyze paint samples directly on curved or irregular surfaces? ATR-FTIR requires good contact between the sample and crystal surface. While flat samples yield optimal results, curved surfaces can be analyzed if sufficient contact can be established. For highly irregular surfaces, micro-ATR accessories with smaller crystal surfaces may improve contact.

Q2: How does ATR-FTIR compare to traditional transmission FTIR for paint analysis? ATR-FTIR requires virtually no sample preparation, while transmission FTIR typically requires creating KBr pellets or thin sections, which is destructive and time-consuming [30]. ATR-FTIR also enables direct analysis of paint chips without dissolution or embedding.

Q3: What is the minimum sample size required for ATR-FTIR analysis? While macro ATR accessories can analyze samples visible to the naked eye, microscopic paint fragments may require FTIR microscopy. For contaminants on paints, particles as small as several hundred microns can be analyzed with macro ATR methods [42].

Q4: How does sample age and degradation affect ATR-FTIR analysis of paints? Environmental degradation and weathering can alter paint chemistry over time. Studies suggest limiting analysis to samples under 10 years old when possible to minimize misclassification due to degradation products [41].

Q5: Can ATR-FTIR distinguish between different layers in multi-layer paint samples? The shallow penetration depth of ATR-FTIR (typically 0.5-2 μm) makes it primarily sensitive to the surface layer. For layer-specific analysis, cross-sectioning followed by micro-ATR FTIR or FTIR microscopy is recommended.

Advanced Applications: Direct Substrate Analysis Workflow

The visualization below outlines the systematic approach for analyzing paint samples directly on various substrates using ATR-FTIR, particularly valuable in forensic contexts where sample removal is undesirable.

ATR-FTIR spectroscopy represents a gold standard for analyzing challenging paint samples with minimal preparation. Its non-destructive nature, combined with direct substrate analysis capability, makes it particularly valuable for forensic investigations, quality control, and materials characterization. By implementing the methodologies, troubleshooting approaches, and experimental protocols outlined in this technical guide, researchers can reliably extract comprehensive chemical information from even the most difficult paint samples while preserving sample integrity for subsequent analyses.

Attenuated Total Reflectance (ATR) Fourier-transform infrared (FTIR) spectroscopy has become the dominant technique for analyzing paint samples due to its minimal sample preparation requirements and ability to handle challenging materials. For researchers analyzing paint hardness and acidity, selecting the appropriate ATR crystal is crucial for obtaining accurate, reproducible results while protecting expensive instrumentation. Paint samples present unique analytical challenges, including complex stratigraphy, low concentrations of organic materials within a largely inorganic matrix, high porosity, and potential exposure to severe environmental conditions [43] [44]. The inherent characteristics of paint samples necessitate careful consideration of crystal properties to ensure compatibility with sample hardness, pH, and spectral requirements. This guide provides comprehensive troubleshooting and FAQs to assist researchers in selecting optimal ATR crystals for their specific paint analysis applications.

ATR Crystal Selection Guide

Key Selection Criteria

When selecting an ATR crystal for paint analysis, several critical factors must be considered to ensure optimal performance and crystal longevity:

Refractive Index: The crystal must have a higher refractive index than the sample to ensure proper internal reflection. Most organic materials in paints have refractive indices around 1.5, while standard ATR crystals range from 2.2 to 4.0 [45] [46]. Inappropriate refractive index ratios can cause distortion of spectral features, diminished peak symmetries, and derivative-like features in the spectrum.

Spectral Range: Different crystal materials provide access to different spectral regions. The low wavenumber cutoff varies significantly between crystals—from approximately 780 cmâ»Â¹ for Germanium to 250 cmâ»Â¹ for KRS-5 [45]. Ensure your crystal's range encompasses the spectral features of interest in your paint samples.

Chemical Compatibility: The crystal must withstand the chemical properties of your samples, particularly pH. For example, ZnSe crystals can be etched by acidic solutions (pH<5), potentially generating toxic hydrogen selenide [45] [46]. Similarly, strong alkalies (pH>9) can damage ZnSe and AMTIR crystals [46].

Physical Durability: Sample hardness must be compatible with crystal durability. Hard, abrasive paint samples require crystals with high pressure resistance, while softer samples can be analyzed with more fragile crystals [47] [48].

Sensitivity Requirements: The effective pathlength is influenced by the number of reflections and depth of penetration. For low-concentration analytes in paint samples, multiple reflections increase absorbance signals [45] [46].

Comparative Analysis of ATR Crystals

The following table summarizes the key properties of the three most common ATR crystals relevant to paint analysis:

Table: Comprehensive Comparison of ATR Crystals for Paint Analysis

| Property | Diamond | Zinc Selenide (ZnSe) | Germanium (Ge) |

|---|---|---|---|

| Refractive Index | 2.4 [45] [48] | 2.4 [45] [48] | 4.0 [45] [48] |

| Spectral Range (cmâ»Â¹) | 45,000-10 [48] (Standard: 7,800-400 [47]) | 20,000-500 [48] (7,800-550 [47]) | 5,000-600 [48] (5,500-480 [47]) |

| Hardness (Knoop) | 9,000 [48] | 120 [45] (Knoop: 130 [48]) | 550 [45] [48] |

| pH Range | 1-14 [45] | 5-9 [46] [47] | 1-14 [45] |

| Penetration Depth | 1.66 μm [48] | 2.0 μm [45] | 0.66 μm [45] |

| Chemical Resistance | Excellent - resistant to strong acids and bases [46] [48] | Poor - reacts with acids and strong bases [46] [47] | Good - insoluble in water, affected by strong acids [46] |

| Relative Cost | Highest [46] | Lowest [46] | Moderate [46] |

| Ideal Paint Applications | Hard, abrasive coatings; acidic/alkaline paints; general purpose [48] | Soft, neutral pH paints; high signal-to-noise requirements [47] | High refractive index paints; surface studies; strongly absorbing samples [47] [48] |

Decision Workflow for Crystal Selection

The following diagram illustrates the systematic process for selecting the appropriate ATR crystal based on paint sample properties:

Troubleshooting Common ATR Crystal Problems with Paint Samples

Spectral Artifacts and Distortions

- Problem: Derivative-like features or diminished peak symmetries in spectra.

- Cause: Refractive index of crystal too close to that of sample (nc ≈ ns), causing anomalous dispersion [47].

Solution: Switch to a higher refractive index crystal (e.g., Germanium with nc=4.0) to maintain nc >> ns condition [47]. For carbon-black filled paints or high-refractive index samples, Germanium is particularly effective at minimizing these distortions.

Problem: Consistently weak absorbance signals across all peaks.

- Cause: Insufficient contact between sample and crystal, or insufficient number of reflections.

- Solution: Ensure adequate pressure is applied to solid samples. For liquid paints, confirm full coverage. Consider a multi-bounce ATR accessory for increased sensitivity [46] [48].

Crystal Damage and Degradation

- Problem: Etching or surface damage on crystal.

- Cause: Chemical incompatibility between crystal and sample pH. ZnSe is particularly vulnerable to acids (pH<5) and strong bases (pH>9) [45] [46].

Solution: For acidic paint samples (e.g., some industrial coatings) or alkaline samples (e.g., fresco paints), use diamond ATR crystals which withstand pH 1-14 [45]. Always test sample pH before analysis if possible.

Problem: Cracks or breakage in crystal.

- Cause: Physical incompatibility - applying excessive pressure to fragile crystals or analyzing hard paints with soft crystals.

- Solution: Match crystal hardness to sample hardness. For hard paint films, use diamond (Knoop hardness: 9,000) rather than ZnSe (Knoop hardness: 130) [45] [48].

Sample Preparation Challenges

- Problem: Spectral contamination from embedding materials.

- Cause: Traditional embedding materials (epoxy, polyester, acrylic resins) infiltrating porous paint samples and interfering with FTIR-ATR spectra [43] [44].

- Solution: Implement alternative preparation techniques using cyclododecane (Câ‚â‚‚Hâ‚‚â‚„) as a temporary consolidant and barrier coating [43] [44]. This method provides necessary support for cross-sectioning via microtoming without spectral interference.

Frequently Asked Questions (FAQs)

Q1: Which ATR crystal is best for routine analysis of historical paint samples with unknown composition?